Selecting the right compact DC motors for your application needs is crucial in an era where precision and efficiency are paramount. According to a recent market analysis by ResearchAndMarkets, the global DC motors market is projected to reach USD 35.2 billion by 2027, indicating a significant rise in demand for compact versions that can deliver high performance in limited spaces. As industries such as robotics, automotive, and telecommunications increasingly rely on compact DC motors for their innovative designs, understanding the specifications and operational requirements of these motors becomes essential. Factors such as torque, speed, and power consumption must be carefully evaluated to ensure optimal functionality and longevity in various applications. This guide aims to provide insights into the selection process, empowering engineers and designers to make informed decisions tailored to their specific project needs.

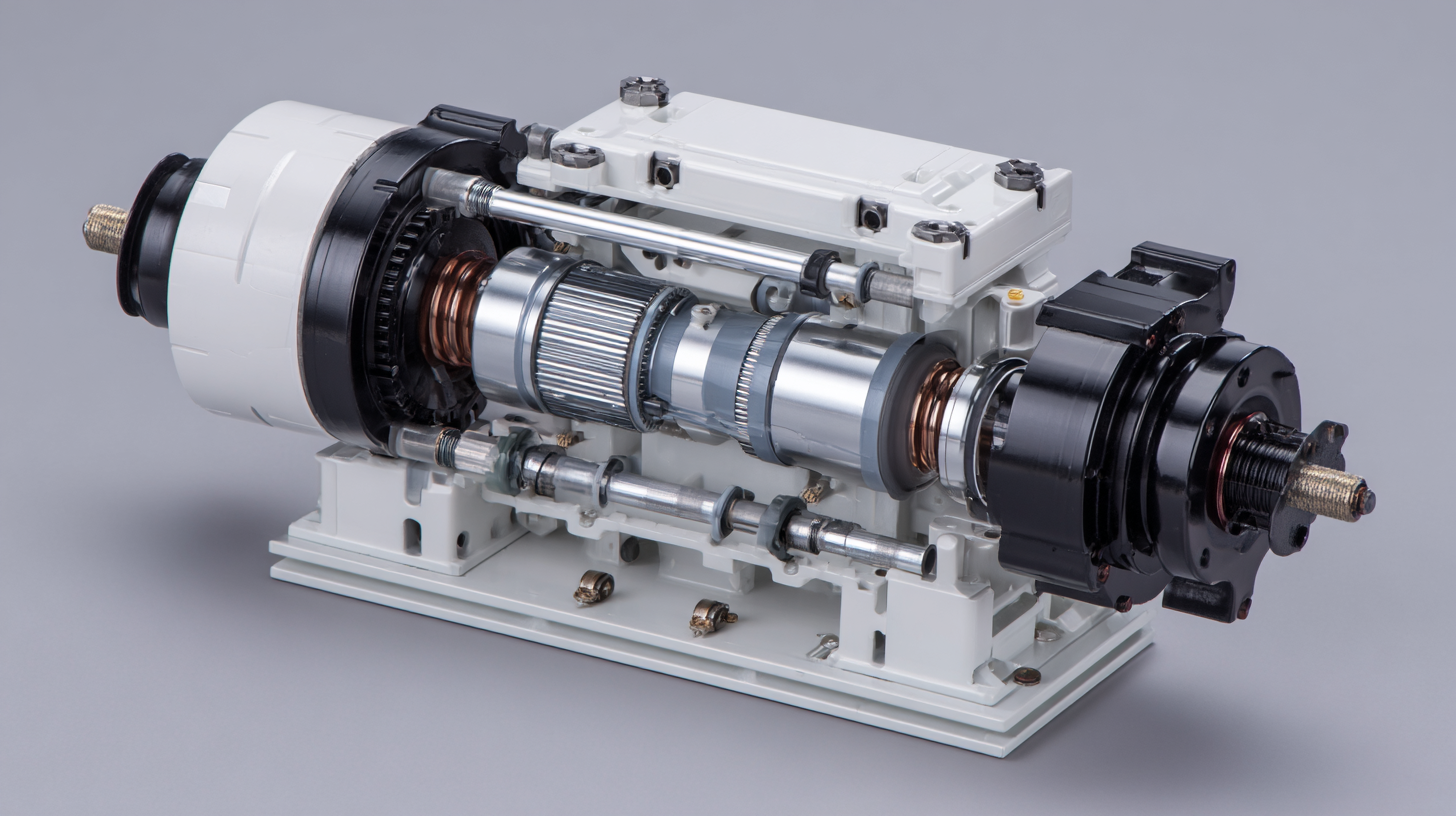

Compact DC motors have become increasingly vital in diverse applications, from electric vehicles to household appliances. These motors, designed for efficiency and space-saving, can be tailored to meet specific power requirements. It is essential to understand the basics of compact DC motors, including their operational attributes and the kinds of applications they are suited for. For instance, the electric motor market for household appliances is projected to grow from $6.50 billion in 2024 to $10.75 billion by 2033, indicating the rising demand for motors that support compact designs and energy efficiency.

Compact DC motors have become increasingly vital in diverse applications, from electric vehicles to household appliances. These motors, designed for efficiency and space-saving, can be tailored to meet specific power requirements. It is essential to understand the basics of compact DC motors, including their operational attributes and the kinds of applications they are suited for. For instance, the electric motor market for household appliances is projected to grow from $6.50 billion in 2024 to $10.75 billion by 2033, indicating the rising demand for motors that support compact designs and energy efficiency.

When selecting the right compact DC motor, consider the motor's voltage, torque, and speed characteristics. Additionally, assess the environment it will be used in—whether it is a high-temperature setting or requires waterproofing—since these factors influence overall performance and longevity.

Tips: Ensure to match the power output of the motor with your application's demands to avoid inefficiency. Additionally, consider the integration of advanced technologies, such as additively manufactured components, which can improve the motor's electrical performance once treated. Always stay updated with the latest trends and innovations in the motor industry to make informed choices.

When selecting the right compact DC motor for your application, it is crucial to identify the key performance specifications that align with your specific needs. Start by assessing the required torque and speed characteristics for your operation. This involves determining the load the motor will drive and the maximum speed at which it must operate. Additionally, consider the voltage and current ratings, as these factors directly impact the motor's performance and efficiency. A thorough understanding of these specifications will ensure that the selected motor can meet the operational demands effectively.

Furthermore, it is essential to evaluate other performance metrics such as efficiency, durability, and thermal management. Higher efficiency motors can lead to energy savings and reduced operational costs, which is particularly important in applications where motors are used continuously. Durability features, such as protective coatings or sealed designs, can enhance the motor's lifespan in challenging environments. Finally, effective thermal management solutions, including heat sinks or cooling systems, should be factored into your selection process to prevent thermal overload, ensuring consistent performance over time. By focusing on these key specifications, you can ensure a well-informed decision in your DC motor selection, tailored to optimize your application’s efficiency and reliability.

When selecting a compact DC motor for your application, evaluating size and form factor is crucial to meeting your specific requirements. Compact DC motors are widely used across various industries, from consumer electronics to automotive applications, where space is often at a premium. According to the market report published by Research and Markets in 2023, the demand for miniaturized motors is projected to grow at an annual rate of 5.2%. This trend indicates a significant shift towards smaller, more efficient motor designs that can fit into tighter spaces without sacrificing performance.

Understanding your application's spatial constraints begins with a detailed assessment of the physical dimensions of potential motors. Key specifications to consider include the diameter, length, and mounting configurations of the motor. For instance, a study by the International Journal of Electrical Engineering noted that motors that are 30% smaller can significantly improve system integration and reduce overall weight without compromising torque output. Additionally, advancements in motor technology have allowed for innovative form factors, such as flattened designs or integrated gear systems that maximize efficiency and fit into unconventional spaces. Choosing the right size and shape ultimately influences not only the motor's functionality but also its longevity and maintenance needs.

When selecting the right compact DC motor for specific applications, understanding power supply and control options is crucial for achieving optimal functionality. According to a report by ResearchAndMarkets, the global market for DC motors is expected to reach $34 billion by 2026, highlighting a surge in demand for efficient power solutions across various industries. A well-matched power supply not only ensures adequate voltage and current for the motor's operation but also enhances its performance, reliability, and lifespan. It is essential to select a power supply that aligns with the motor's specifications, which typically include a voltage rating between 6V to 48V for compact DC motors.

Moreover, implementing advanced control options can significantly impact the performance of the motor. Utilizing pulse width modulation (PWM) for speed control allows for increased efficiency, reducing energy waste by optimizing the power delivered to the motor. According to a study published in the IEEE Transactions on Industrial Electronics, systems leveraging PWM can improve energy efficiency by up to 30%, illustrating the importance of integrating smart control technologies. Evaluating these power supply and control options enables engineers to tailor solutions that not only meet operational requirements but also contribute to sustainable practices within the industry.

When selecting a compact DC motor for your application, cost and reliability play critical roles in the decision-making process. The initial cost of the motor is often a primary factor, but it’s essential to consider the long-term implications of your choice. A cheaper motor might save money upfront, but if it fails frequently, the costs associated with replacements and downtime can quickly outweigh those savings. Reliability should be assessed not only in terms of failure rates but also in how well the motor operates under your specific conditions.

Tip: Always check the manufacturer's specifications for expected lifespan and performance metrics. This information can provide insight into the reliability of the motor over time, helping you make a more informed choice.

Another consideration is the application environment. Motors can be exposed to varying temperatures, humidity, and other factors that influence their performance. Selecting a motor that is designed to withstand your specific conditions will ensure that it operates efficiently and reliably.

Tip: Look for motors that come with a warranty or guarantee. This can provide peace of mind, indicating that the manufacturer stands behind their product and values customer satisfaction.