In the rapidly evolving landscape of motor technology, the integration of BLDC (Brushless Direct Current) Drive systems has marked a significant turning point in the realm of efficiency and performance. According to Dr. Emily Carter, a leading expert in electric motors and automation, "The adoption of BLDC Drive technology is transforming not just the manufacturing process, but also how we understand motor capabilities in various applications." This statement underscores the profound impact BLDC Drives have on not only enhancing operational efficiency but also enabling innovative functionalities across multiple industries.

Modern motors equipped with BLDC Drive technology are equipped to deliver reduced energy consumption and increased reliability, making them ideal for applications ranging from consumer electronics to industrial machinery. As the demand for energy-efficient solutions grows, the shift towards BLDC Drives is not merely a trend but a necessity for future advancements. The precision of these systems allows for better speed control and torque management, ultimately leading to a more sustainable approach in motor applications.

This article will delve deeper into the revolutionary impact of BLDC Drive technology, exploring how it unlocks unprecedented levels of efficiency and reliability in modern motors. By analyzing industry trends and expert insights, we aim to illustrate the integral role BLDC Drives will play in shaping the future of motor technology and energy management.

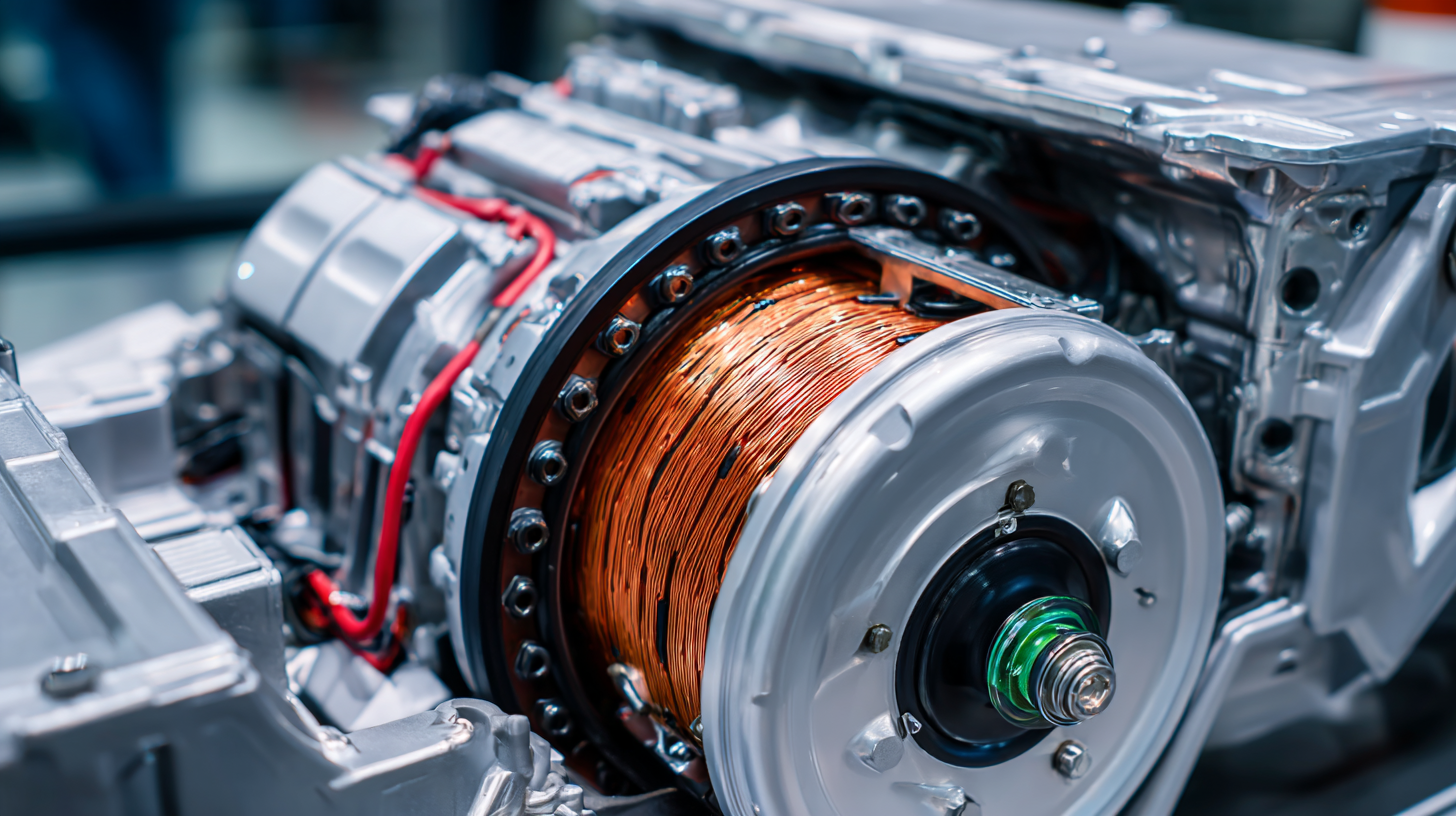

Brushless DC (BLDC) drive technology is revolutionizing the performance of modern motors, particularly in the realm of energy efficiency. One of the most compelling advantages of BLDC motors is their ability to significantly reduce energy consumption compared to traditional motor types. This is particularly critical in applications such as electric tuk-tuks, which are rapidly transforming urban transportation. By employing efficient battery systems and advanced motor control mechanisms, BLDC technology not only leads to lower operational costs but also contributes to reducing carbon emissions.

Tips: When considering a shift to BLDC technology, focus on the design of the motor. Adaptive speed control and innovative rotor designs are key features that enhance efficiency and torque density, making the system more versatile for various applications. Additionally, keeping an eye on industry advancements, such as new semiconductor releases for motor control, can provide insight into the best options available for energy efficiency improvement.

Furthermore, the establishment of mandatory minimum efficiency levels could further accelerate the adoption of BLDC technology across different sectors. This regulatory push reinforces the ongoing shift towards sustainable energy solutions, as industries look to minimize their environmental impact while maximizing performance. As research continues on optimizing BLDC motors for varied applications, the potential for increased efficiency remains promising.

| Aspect | Conventional Motors | BLDC Motors |

|---|---|---|

| Energy Efficiency | 60-80% | 85-95% |

| Operational Lifespan | 1,500-5,000 hours | 10,000-20,000 hours |

| Noise Level | High | Low |

| Size/Weight | Larger | Compact |

| Control Precision | Moderate | High |

| Maintenance | High | Low |

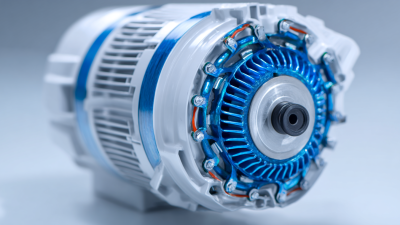

BLDC (Brushless DC) motors represent a significant departure from traditional motor technologies such as brushed DC motors and induction motors. One of the key advantages of BLDC motors is their superior efficiency. According to a report by the International Electrotechnical Commission (IEC), BLDC motors can achieve efficiencies of 85-90%, significantly outpacing the 70-80% efficiency typical of traditional motors. This efficiency is due in large part to the elimination of brushes, which reduces friction and wear, ultimately leading to lower maintenance costs and longer lifespans.

BLDC (Brushless DC) motors represent a significant departure from traditional motor technologies such as brushed DC motors and induction motors. One of the key advantages of BLDC motors is their superior efficiency. According to a report by the International Electrotechnical Commission (IEC), BLDC motors can achieve efficiencies of 85-90%, significantly outpacing the 70-80% efficiency typical of traditional motors. This efficiency is due in large part to the elimination of brushes, which reduces friction and wear, ultimately leading to lower maintenance costs and longer lifespans.

In addition to efficiency, BLDC motors offer improved performance in terms of torque and speed control. The precise control capabilities of BLDC technology result in higher torque-to-weight ratios, making them ideal for applications ranging from electric vehicles to robotics. A study by the Electric Power Research Institute highlights that BLDC motors can deliver 20-30% more torque compared to brushed motors of the same size, thereby enhancing overall system performance.

Tip: When considering motor options for your application, evaluate the long-term savings associated with higher efficiency and lower maintenance needs offered by BLDC technology.

Another point to consider is the environmental impact. BLDC motors generate less heat and noise, contributing to a more sustainable and quieter operation. According to a study by the National Renewable Energy Laboratory (NREL), the adoption of BLDC motors in various industries could reduce energy consumption by as much as 25%, showcasing their role in promoting energy efficiency in modern technology.

Tip: Always assess your specific operational needs and regulatory standards when transitioning from traditional motors to BLDC technology, as this can significantly impact overall effectiveness and compliance.

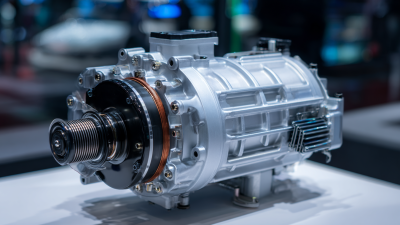

The advancements in Brushless Direct Current (BLDC) drive technology are transforming modern industrial systems, significantly enhancing efficiency and performance. According to recent industry analysis, the brushless DC motor market is projected to reach USD 66.57 billion by 2033, demonstrating a compound annual growth rate (CAGR) of 11.63% from 2025 to 2033. This growth highlights the increasing adoption of BLDC motors across various applications, driven by their superior efficiency and lower maintenance requirements compared to traditional motor technologies.

The role of BLDC drives is particularly prominent in sectors requiring precise control, including robotics, HVAC systems, and electric vehicles. These drives not only reduce energy consumption but also minimize electromagnetic interference (EMI), which is crucial in sensitive industrial environments. Innovations such as new gate drivers are enhancing operational efficiencies with reduced motor heat, making BLDC solutions even more attractive to industries focused on sustainability and cost-effectiveness. The integration of BLDC technology is not just a trend; it's becoming a standard in modern industrial automation, paving the way for smarter and more efficient production processes.

The implementation of Brushless DC (BLDC) drive systems presents several challenges that must be carefully navigated to fully harness their benefits. One significant hurdle is the complexity of the control algorithms required to operate BLDC motors efficiently. Traditional control methods may fall short in optimizing the performance of these advanced systems, leading to issues such as overheating and diminished lifespan. Engineers must invest in developing sophisticated algorithms that can adapt to varied load conditions while maintaining energy efficiency.

Another challenge is the integration of BLDC motors into existing infrastructure. Many industries rely on legacy systems that utilize brushed motors, posing compatibility concerns. Transitioning to BLDC technology necessitates not only the sourcing of compatible components but also retraining personnel to manage and maintain the new systems. To address these issues, manufacturers are focusing on creating modular designs that facilitate easier replacements and enhancements, while training programs are being established to equip workers with the necessary skills to operate and maintain BLDC drive systems effectively.

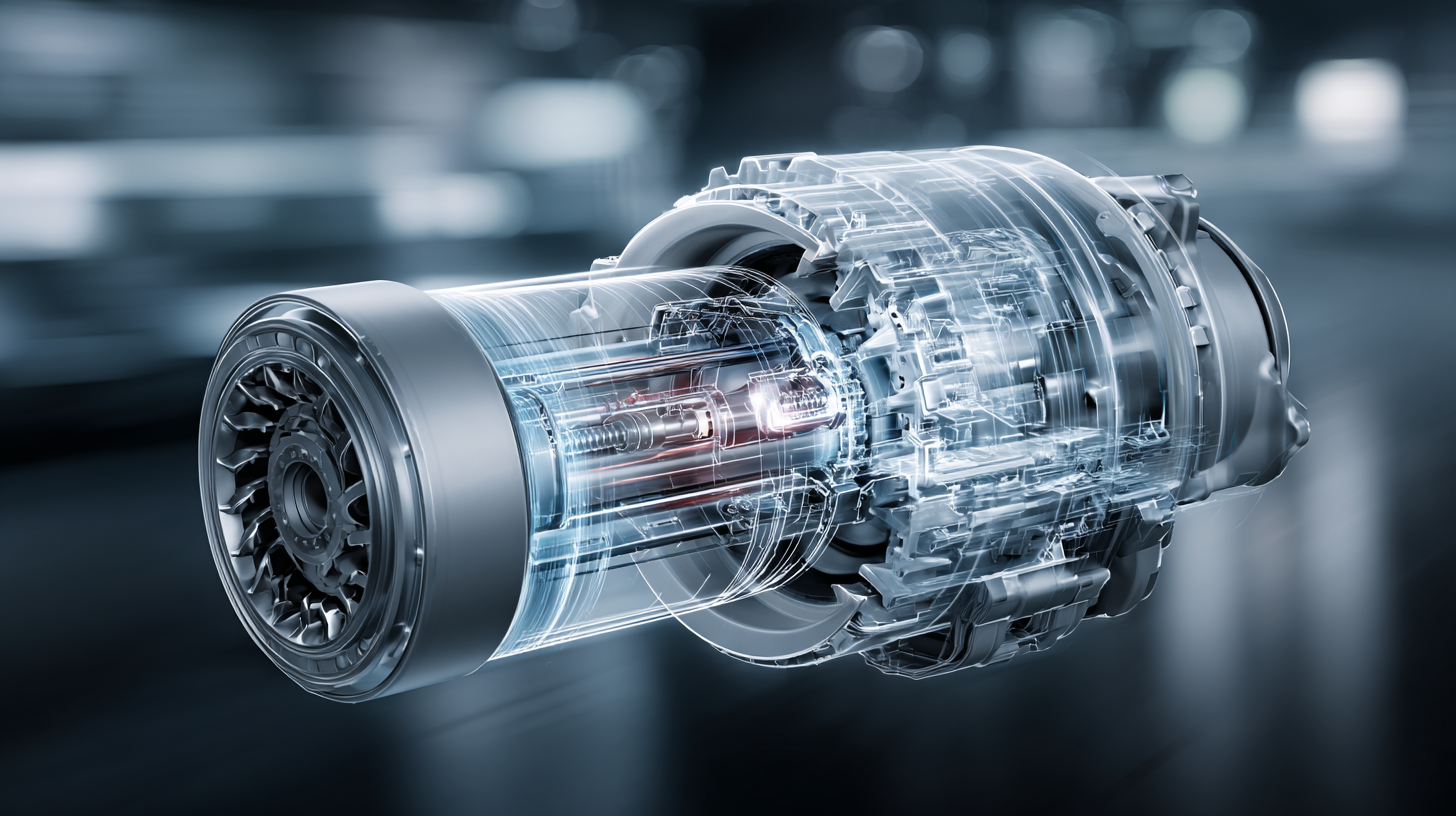

The recent advancements in Brushless DC (BLDC) technology are setting the stage for a transformative future in motor innovation. As the demand for energy-efficient solutions rises, industries are increasingly looking towards BLDC motors for a wide array of applications. Notably, the integration of innovative control and drive technologies is reshaping the landscape, allowing manufacturers to produce motors that are not only efficient but are also smarter in terms of performance and adaptability.

The emergence of new players in the market highlights the growing significance of BLDC technology. According to industry experts, the motor control sector is witnessing a transition towards more integrated and compact systems, reflecting broader technological advancements. Current trends suggest that as industries embrace automation and energy-saving policies, the demand for high-performance BLDC motors will continue to surge. This shift is further fueled by robust market projections that estimate substantial growth in the sector, emphasizing the continued evolution of motor control technologies as they adapt to new efficiency standards and smart home applications.