As industries increasingly prioritize efficiency and performance, the integration of PMDC motors into application designs is becoming paramount. According to a report by MarketsandMarkets, the global electric motor market, which includes PMDC motors, is projected to reach USD 156.2 billion by 2025, growing at a CAGR of 7.7%. This growth is driven by the need for energy-efficient solutions across various sectors, including automotive, aerospace, and industrial automation.

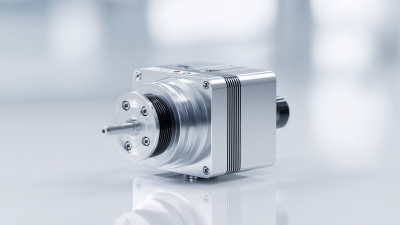

By harnessing the unique advantages of PMDC motor technology—such as compact size, high torque density, and simplified control mechanisms—engineers can significantly enhance the efficiency and reliability of their applications.

Understanding how to optimize your applications with PMDC motors not only contributes to reducing operational costs but also aligns with the broader trend towards sustainable engineering practices in a rapidly evolving market.

Permanent Magnet Direct Current (PMDC) motor technology is increasingly recognized for its efficiency and performance in various applications. Recent industry studies indicate that PMDC motors can achieve efficiency rates of up to 90%, significantly higher than traditional brushed DC motors, which are typically in the range of 70-80%. This efficiency translates to reduced energy consumption and lower operating costs, making PMDC motors an ideal choice for energy-sensitive applications, such as electric vehicles and industrial automation.

One of the primary benefits of PMDC motors is their compact design, which allows for application in space-constrained environments without compromising performance. A report from the International Electrotechnical Commission (IEC) highlights that the small physical footprint of PMDC motors enables manufacturers to design lighter, more efficient systems, thereby enhancing overall product viability. Additionally, the low maintenance requirements associated with PMDC technology—due to the absence of brushes—result in longer operational life and reduced downtime, further adding to their appeal in a wide range of commercial and industrial sectors.

| Application Area | Power Rating (W) | Voltage (V) | Efficiency (%) | Torque (Nm) | Speed (RPM) |

|---|---|---|---|---|---|

| Electric Vehicles | 5000 | 48 | 85 | 10 | 3000 |

| Robotics | 300 | 24 | 90 | 0.5 | 250 |

| Industrial Automation | 2000 | 220 | 92 | 5 | 1500 |

| Home Appliances | 100 | 12 | 80 | 0.2 | 3000 |

| Medical Devices | 50 | 12 | 95 | 0.1 | 1800 |

When selecting Permanent Magnet Direct Current (PMDC) motors for your applications, several key factors are essential to ensure optimal performance and efficiency. First, consider the power output requirements of your application. PMDC motors can be categorized into fractional horsepower (up to 1HP) and integral horsepower (above 1HP), which directly influences the motor's capabilities and suitability for specific tasks. Understanding the necessary torque and speed characteristics will help in choosing the right motor size and configuration.

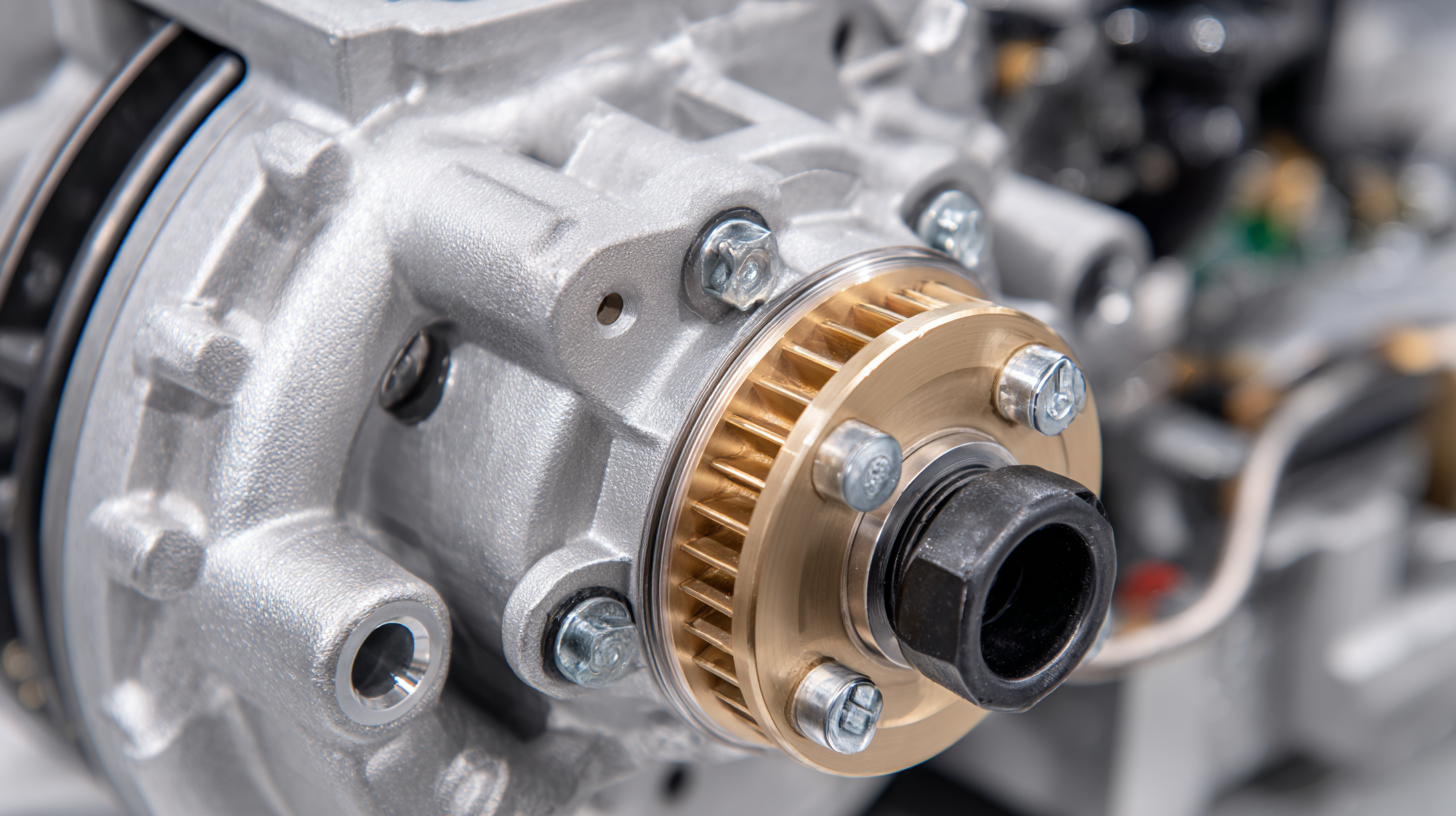

Additionally, voltage is crucial when selecting PMDC motors. As the market evolves, with projections indicating a significant growth rate, it’s vital to align the motor specifications with your system's electrical standards to maximize reliability and minimize energy consumption. Integration with existing systems is another consideration; the compatibility of the PMDC motor with converters and controllers will affect the overall efficiency and performance. By evaluating these factors, you can optimize your applications effectively, harnessing the advancements in motor technology to drive innovation and enhance operational efficiency.

To enhance efficiency in Permanent Magnet Direct Current (PMDC) motor-driven systems, it is essential to implement robust techniques that optimize performance. One key method involves precise control of motor speed and torque. By employing advanced algorithms like Field Oriented Control (FOC), systems can maintain the desired performance while minimizing energy losses. This level of control not only improves the responsiveness of the motor but also extends its operational lifespan by reducing thermal stress.

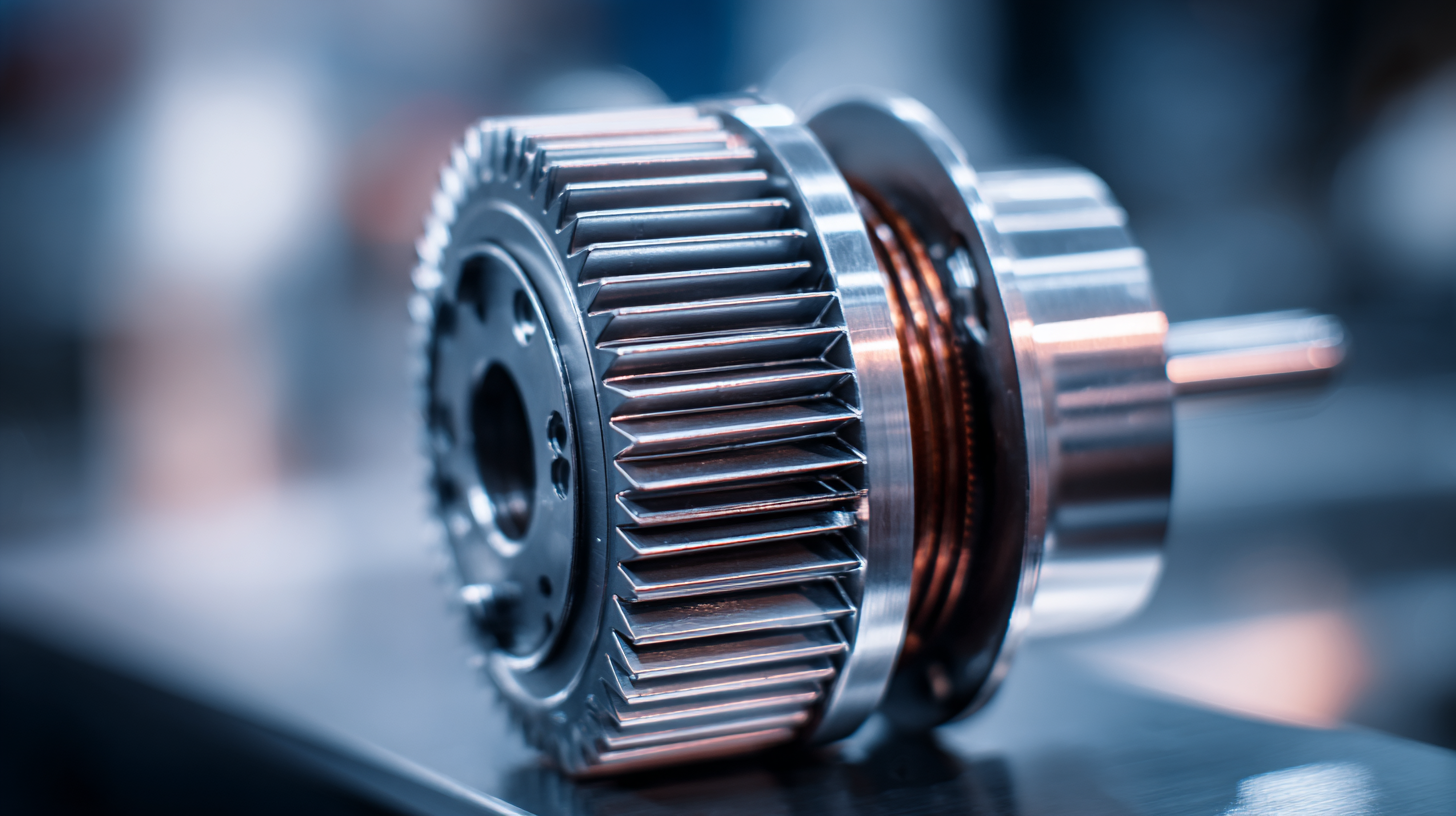

Another effective technique is the use of high-quality materials for the motor components. Selecting superior magnets and conductive materials can significantly decrease energy consumption and improve overall efficiency. Additionally, proper sizing and matching of the PMDC motor to the application requirements is crucial. An over-sized motor will operate inefficiently, leading to unnecessary energy waste. Regular maintenance and monitoring also play a vital role, as keeping the system in optimal condition ensures that efficiency levels remain high and that any potential issues are addressed before they escalate.

Integrating Permanent Magnet DC (PMDC) motors with control systems is pivotal for maximizing the performance of various applications. By aligning the motor's characteristics with sophisticated control algorithms, engineers can enhance efficiency and responsiveness. One effective approach is to utilize field-oriented control (FOC), which optimally manages the torque and speed of PMDC motors, resulting in smoother operations and reduced energy consumption. This integration not only improves the overall functionality of the system but also prolongs the lifespan of the motor by minimizing thermal stress and wear.

Moreover, employing sensor feedback mechanisms in conjunction with PMDC motors allows for real-time monitoring and adjustments. This feedback loop can dynamically adapt the control parameters to varying load conditions, optimizing performance in scenarios where environmental or operational factors change rapidly. As a result, applications ranging from robotics to electric vehicles benefit from increased reliability and precision. By prioritizing these integration techniques, developers can achieve not only enhanced performance but also a more sustainable operational footprint.

When working with Permanent Magnet Direct Current (PMDC) motors, engineers frequently face several challenges that can hinder optimal performance. One common issue is thermal management; PMDC motors can overheat, leading to reduced efficiency and a shorter lifespan. To mitigate this, implementing enhanced cooling systems or choosing motors with better thermal ratings can be beneficial.

Another challenge is efficiency losses due to friction and electrical resistance. This can result in diminished torque and increased energy consumption. Regular maintenance, such as lubricating moving parts and ensuring proper electrical connections, is crucial. Additionally, selecting high-quality components when assembling your PMDC motor system can significantly reduce these losses.

**Tips:** To boost the performance of PMDC motors, consider integrating a closed-loop control system. This allows for real-time adjustments and improves operational efficiency. Also, using soft-start techniques can help reduce stress on the motor during startup, prolonging its service life. Finally, thorough testing under different load conditions will provide insights into performance and help in fine-tuning the application.