In today's rapidly evolving technological landscape, the demand for efficient and high-performance solutions has never been greater, particularly in sectors such as robotics, automotive, and manufacturing. Recent reports indicate that the market for brushless motor technology, particularly those utilizing high torque capabilities, is poised for significant growth, projected to reach $40 billion by 2025 (MarketsandMarkets). This surge can be attributed to their enhanced efficiency, lower maintenance requirements, and superior performance compared to traditional brushed motors. Brushless Motor High Torque designs are not only crucial for improving energy consumption and reducing operational costs but also play a vital role in achieving sustainability goals across various industries. As businesses strive to optimize their operations, understanding and harnessing the benefits of brushless motor technology becomes imperative for maximizing productivity and ensuring competitiveness in a dynamic marketplace.

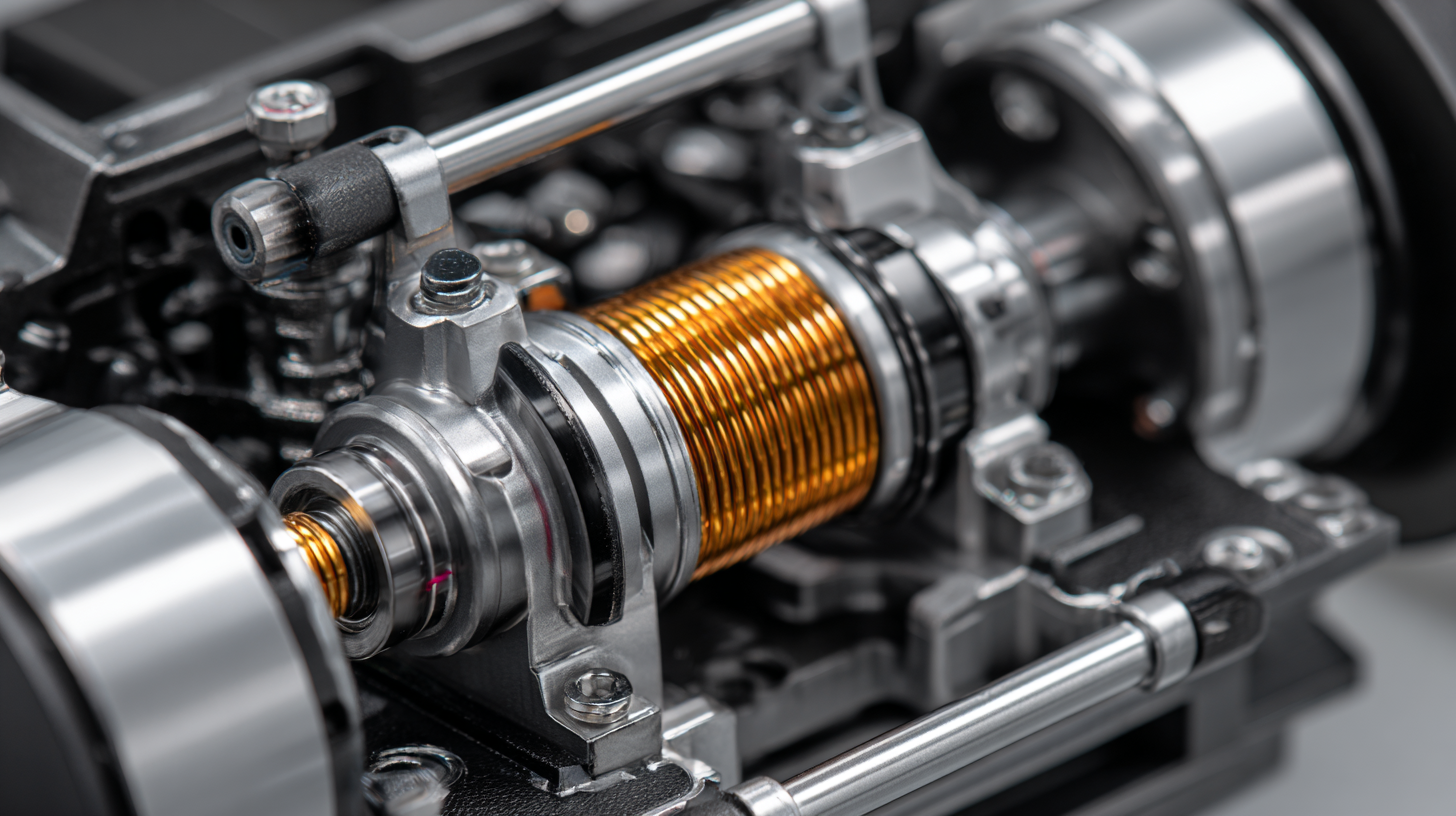

The advancements in brushless motor technology have significantly enhanced torque efficiency, crucial for various applications, including robotics and electric vehicles. Research indicates that the global high torque stepper motor market is projected to surge from USD 1.21 billion in 2025 to approximately USD 1.94 billion by 2034, highlighting a growing demand for innovative motion solutions. Enhanced torque density and adaptive speed control mechanisms, such as those implemented through fuzzy logic, are driving improved precision and control in robotic designs.

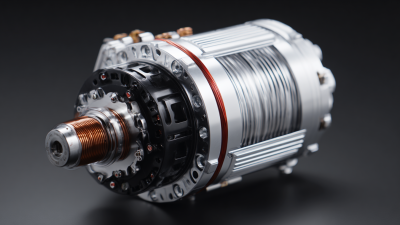

Moreover, optimizing rotor designs in brushless DC motors (BLDC) contributes to maximizing efficiency and torque density. Innovations like open rotor designs not only enhance motor performance but also extend operational capabilities in various applications, from electric vehicles to solar water pumping systems. Furthermore, comparative analyses of BLDC and switched reluctance motors for off-grid water pumping demonstrate significant potential for enhanced efficiency, showing the critical role brushless motor technology plays in modern industrial automation and environmental solutions. These developments confirm the ongoing trend toward higher efficiency and performance in brushless motor applications.

Brushless motors have gained significant traction in various industries due to their superior performance compared to traditional brushed motors. According to a report by the International Electrotechnical Commission, brushless motors exhibit up to 95% efficiency, as opposed to the 70-85% efficiency typically seen in brushed alternatives. This remarkable efficiency translates into lower energy costs and reduced heat generation, making brushless motors ideal for applications requiring high torque and longevity.

Performance metrics also highlight the torque capabilities of brushless motors. Research from the Advanced MotorTech Institute indicates that brushless motors can produce up to 3 times the torque of brushed motors in similar sizes. This capability allows for faster acceleration and more robust operation in demanding conditions. Additionally, brushless motors eliminate the need for periodic maintenance associated with brush wear, thereby enhancing operational uptime and reliability. The adoption of brushless technology is on the rise, with market forecasts predicting a compound annual growth rate of 10% through 2025, as industries seek more efficient and powerful alternatives for their applications.

High torque brushless motors are increasingly becoming a staple in various industries due to their remarkable efficiency and performance. These motors are particularly suited for applications requiring high torque output and precision control. For instance, in the electric vehicle (EV) sector, brushless motors deliver exceptional torque at low speeds, making them ideal for applications like drivetrains where quick acceleration is essential. According to a report by the International Council on Clean Transportation, electric vehicles utilizing brushless motor technology can achieve up to 21% more efficiency compared to conventional AC motors, significantly enhancing overall performance.

In manufacturing, high torque brushless motors play a crucial role in automation and robotics. Their ability to maintain high torque at variable speeds allows them to operate various machines with precision, reducing downtime and improving productivity. The Robotics Industries Association notes that incorporating brushless motors in robotic arms can increase payload capacities by up to 30%, facilitating the handling of heavier components with ease. Additionally, in the aerospace domain, these motors enable precision control for actuators and flight systems, contributing to safer and more efficient operation of aircraft while meeting stringent weight constraints.

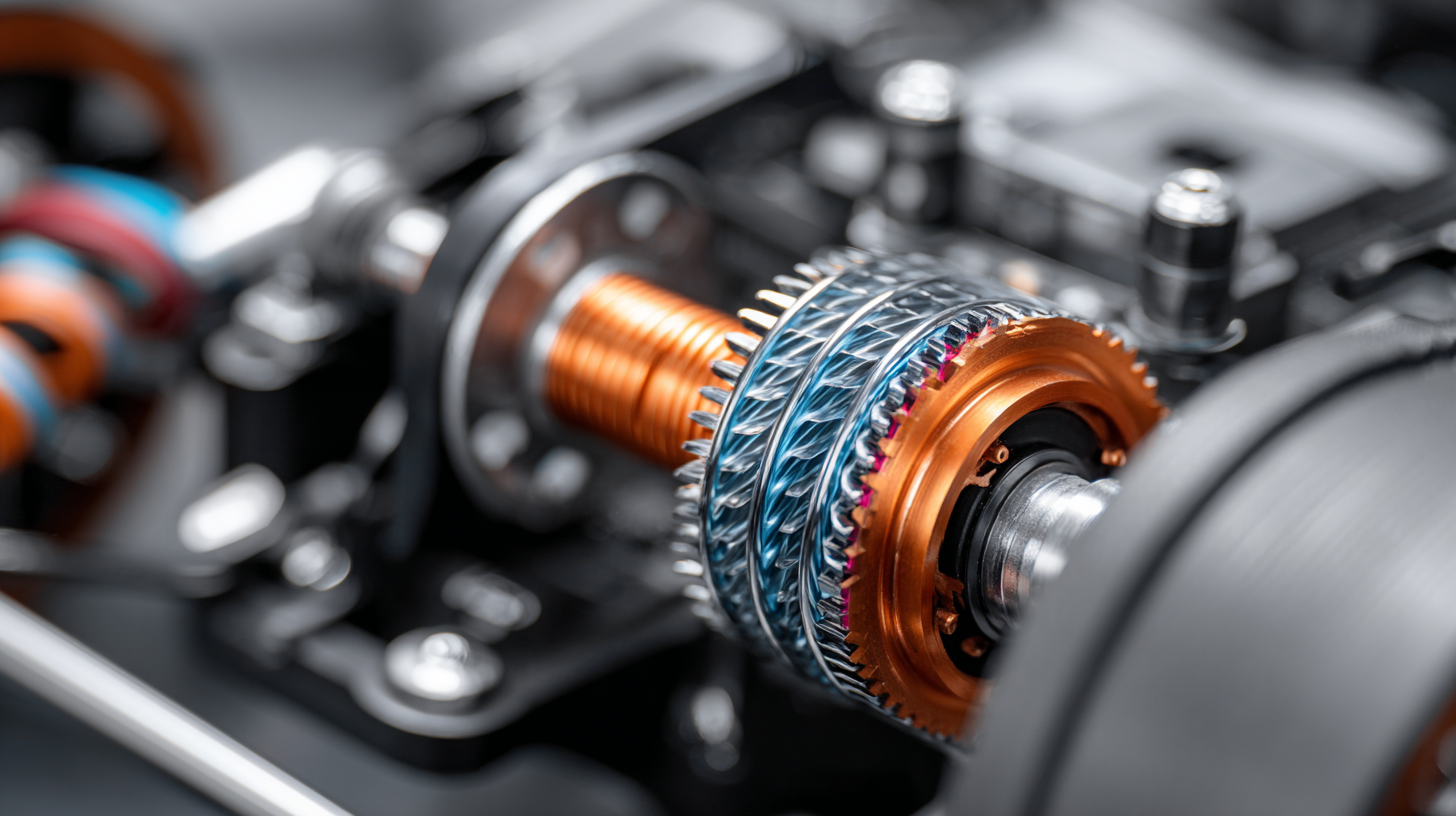

Utilizing brushless motors in these optimal application scenarios not only maximizes efficiency but also drives innovation in design and engineering across multiple sectors. As industries continue to evolve, the demand for high torque brushless motors is expected to grow, highlighting their pivotal role in modern technology.

Brushless motors are at the forefront of electric vehicle (EV) technology, offering high torque capabilities that significantly enhance efficiency and performance. To ensure the longevity and efficiency of brushless motors, implementing best maintenance practices is crucial. Routine checks for wear and tightening connections reduce the likelihood of costly failures. According to recent surveys, maintaining optimal operating temperatures can lead to a 20% increase in motor longevity, which aligns with the broader sustainability goals of the EV industry as it rapidly evolves to meet the demand for reduced carbon emissions.

Additionally, advancements in battery technology are integral to maximizing the efficiency of brushless motors in electric vehicles. The latest data indicate that well-maintained lithium-ion batteries can last over a decade, supporting the efficient operation of high-torque brushless motors. As the market for electric vehicles continues to expand, it is essential to develop systematic approaches for energy storage that complement these motor technologies. Proper care and management of both brushless motors and their associated batteries will not only ensure optimal performance but also contribute to sustainable practices within the electric vehicle sector.

| Tip | Description | Maintenance Frequency | Expected Benefits |

|---|---|---|---|

| Regular Lubrication | Ensure adequate lubrication to reduce wear and friction. | Every 500 hours of operation | Extended motor life and improved performance. |

| Regular Cleaning | Keep motor surfaces clean to prevent dust accumulation. | Monthly | Improves cooling efficiency and reduces overheating risks. |

| Check Electrical Connections | Inspect wiring and connectors for any signs of wear or damage. | Every 100 hours of operation | Prevention of electrical failures and improved safety. |

| Monitor Temperature | Keep an eye on operating temperatures to avoid overheating. | Daily | Ensures optimal performance and flags potential issues early. |

| Load Management | Operate within specified load limits to prevent strain on the motor. | Ongoing | Increases overall efficiency and motor lifespan. |

When working with brushless motor systems, understanding power supply considerations is crucial for maximizing output. One of the first steps is to select a power supply that matches the voltage and current requirements of your specific motor. This ensures optimal performance and reliability, preventing issues like overheating or underperformance. Additionally, implementing a power supply with ample capacity can accommodate peak demands during operation, thereby enhancing the overall efficiency of the system.

Another important factor is the quality of the power supply. Using a high-quality, regulated power source minimizes noise and voltage fluctuations, which can affect the motor's performance. Integrating capacitors and filters in the circuitry can further stabilize the power supply, allowing for smoother operation. It's also essential to consider the wiring and connectors used in the setup, as low-quality components can lead to significant power losses. By meticulously planning the power supply aspects, users can leverage the full potential of brushless motor high torque technology, achieving superior performance and efficiency.