As the demand for energy-efficient and high-performance solutions continues to rise, the spotlight is increasingly on Large Brushless Motors, which are becoming pivotal in a variety of industrial applications. According to a recent report by the International Electrotechnical Commission, the market for brushless motors is projected to witness substantial growth, estimated to reach USD 15 billion by 2026, driven by advancements in technologies such as IoT and automation.

Innovations in large brushless motor designs are not only enhancing performance across sectors such as manufacturing, automotive, and robotics, but are also contributing significantly to energy savings and reduced carbon emissions. As industries increasingly prioritize sustainability and efficiency, understanding the latest developments and applications of Large Brushless Motors is paramount for technology leaders and business decision-makers keen on staying ahead in a competitive landscape.

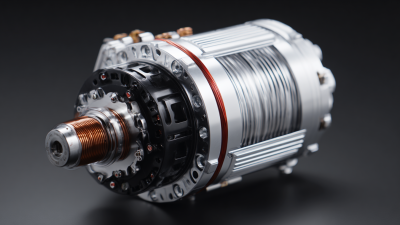

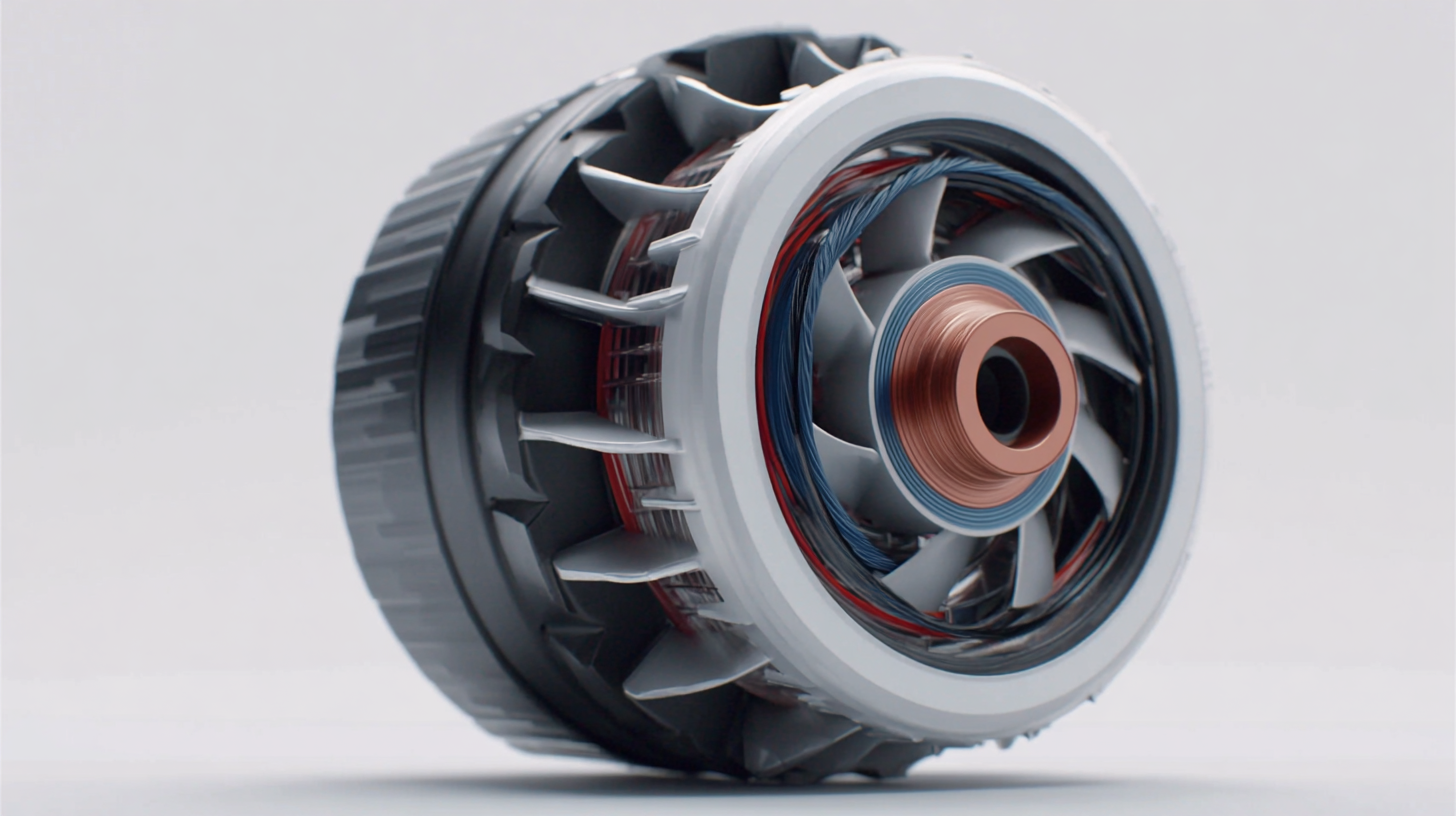

Large brushless motors are revolutionizing the way we approach modern applications, particularly in industries that demand efficiency and precision. Unlike traditional brushed motors, brushless motors eliminate physical contact between moving parts, resulting in reduced wear and improved reliability. Understanding the mechanics behind these motors reveals their exceptional performance characteristics, such as high torque-to-weight ratios, rapid acceleration, and silent operation. This makes them ideal for applications in aerospace, renewable energy, and robotics.

Tip: When selecting a large brushless motor for your project, consider the motor's torque curve and power requirements. Matching these specifications to your application can lead to optimal performance.

Moreover, innovations in digital control technologies are enabling even greater advancements in the functionality of large brushless motors. By utilizing advanced algorithms and real-time data feedback, these motors can adapt dynamically to varying loads and conditions, enhancing their efficiency and lifespan. As a result, industries are increasingly turning to brushless solutions to meet their operational goals.

Tip: Ensure proper cooling mechanisms are in place for your brushless motor. Overheating can reduce performance and lead to premature failure, so effective thermal management is crucial.

The landscape of electric motors, particularly brushless types, is undergoing remarkable transformations fueled by innovative technologies. As industries progressively embrace automation and smart systems, brushless micro electric motors are emerging as essential components, thanks to their compact size and energy efficiency. These motors are finding applications in areas ranging from robotics to household appliances, revolutionizing how devices operate by enhancing performance while minimizing energy consumption.

An essential factor driving this evolution is the increasing demand for energy-efficient solutions across various sectors. The electric motor market is projected to significantly expand, with a noteworthy compound annual growth rate (CAGR) reflecting the industry's shift toward sustainability and advanced technology. Additionally, the ongoing advancements in electric motor design—including features that enhance energy efficiency and adaptability—are vital as they align with the growing focus on reducing carbon footprints. With innovations such as application-specific motors, industries are poised to maximize productivity while adhering to sustainability goals, paving the way for a more environmentally conscious future.

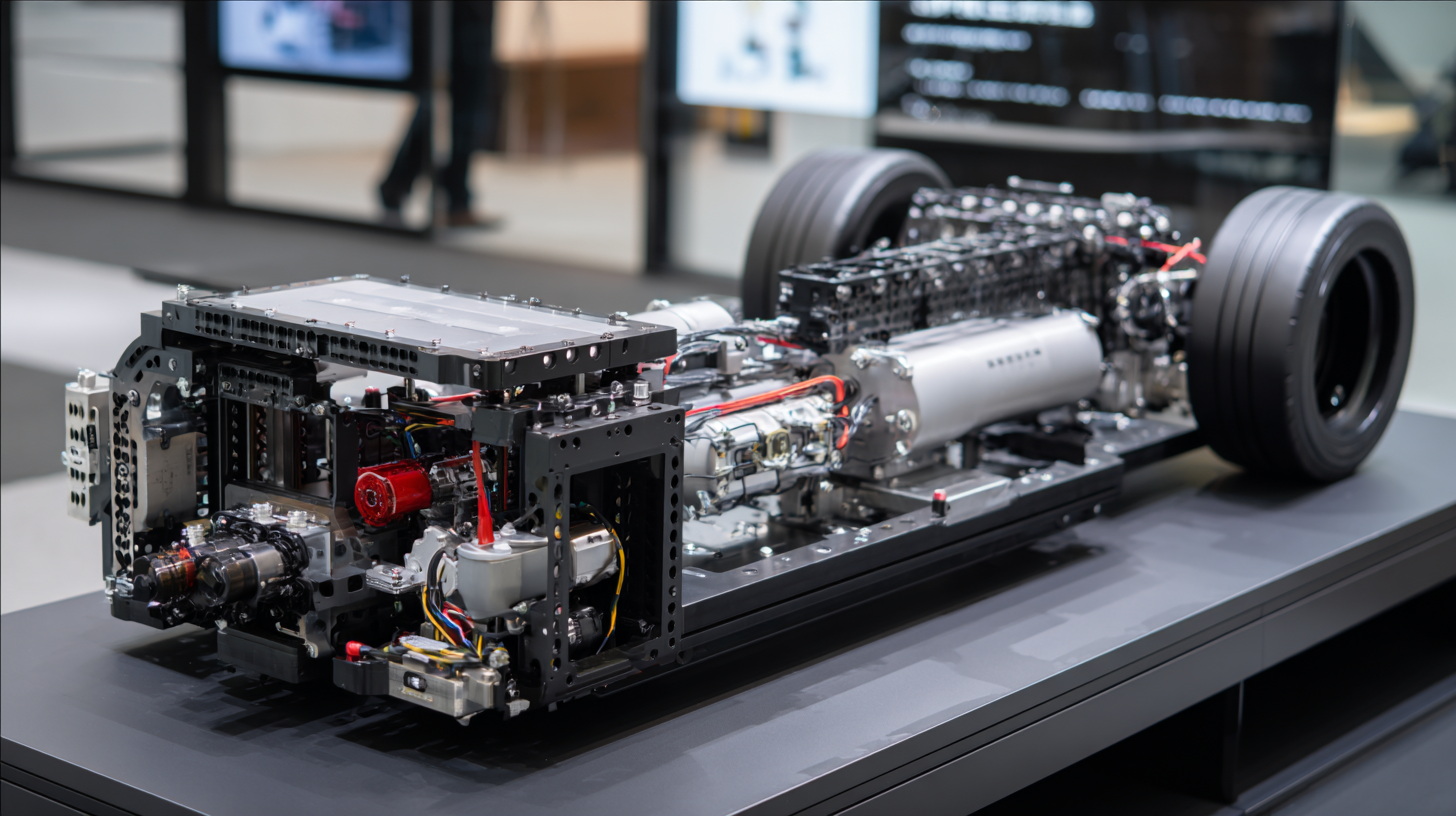

Large brushless motors are increasingly being integrated into renewable energy solutions, demonstrating their essential role in advancing sustainable technologies. Their efficiency, durability, and ability to provide high torque at low speeds make them ideal for applications such as wind turbines, solar tracking systems, and energy storage systems. These motors enhance the performance of renewable energy facilities by enabling more reliable and efficient operation, reducing energy waste and operational costs.

As the demand for renewable energy continues to grow, the market for large brushless motors is expected to expand significantly. Innovations in motor technology, like advanced electronic control systems, enhance their capabilities, allowing for better integration with digital power conversion systems. This integration is crucial for optimizing performance in applications ranging from electric vehicles to offshore wind farms, where precise control and high reliability are paramount. With continuous advancements, large brushless motors are poised to play a pivotal role in the transition to cleaner energy solutions.

The future of large brushless motors is poised to witness revolutionary innovations, driven by rapid technological advancements and evolving market needs. As industries continue to prioritize efficiency and sustainability, brushless motors are expected to play a pivotal role in various applications, from electric vehicles to automation in manufacturing. This transformation reflects a broader trend in motor technology, suggesting that we are on the brink of significant breakthroughs in performance, reliability, and energy efficiency.

In particular, the electric vehicle market is projected to experience substantial growth, with global sales expected to soar from $29.69 billion in 2025 to $40.95 billion by 2032, showcasing a compound annual growth rate of 4.7%. This growth is indicative of heightened demand for improved battery systems and advanced motor designs, which are essential for enhancing vehicle performance. Additionally, innovations in automotive chip technology, targeting smarter embedded systems and real-time communication, will further drive the evolution of brushless motors, integrating them into the fabric of smart mobility solutions for the future.

| Innovation Area | Description | Expected Impact | Potential Applications |

|---|---|---|---|

| AI-Driven Control Systems | Integration of AI for predictive maintenance and efficient motor operation. | Enhanced reliability and reduced downtime. | Robotics, Manufacturing Automation |

| Wireless Technology | Use of wireless communication for remote monitoring and control. | Increased flexibility and reduced wiring costs. | Industrial Machinery, Electric Vehicles |

| Advanced Materials | Utilizing lightweight, high-strength materials for better efficiency. | Higher performance and energy savings. | Aerospace, Automotive |

| Modular Motor Designs | Designing motors in a modular fashion for easier scalability. | Versatile applications and quick adaptations. | Renewable Energy, Smart Grids |

| Enhanced Cooling Solutions | New cooling technologies to improve thermal management. | Longer lifespan and improved efficiency. | Heavy Machinery, Electric Power Tools |

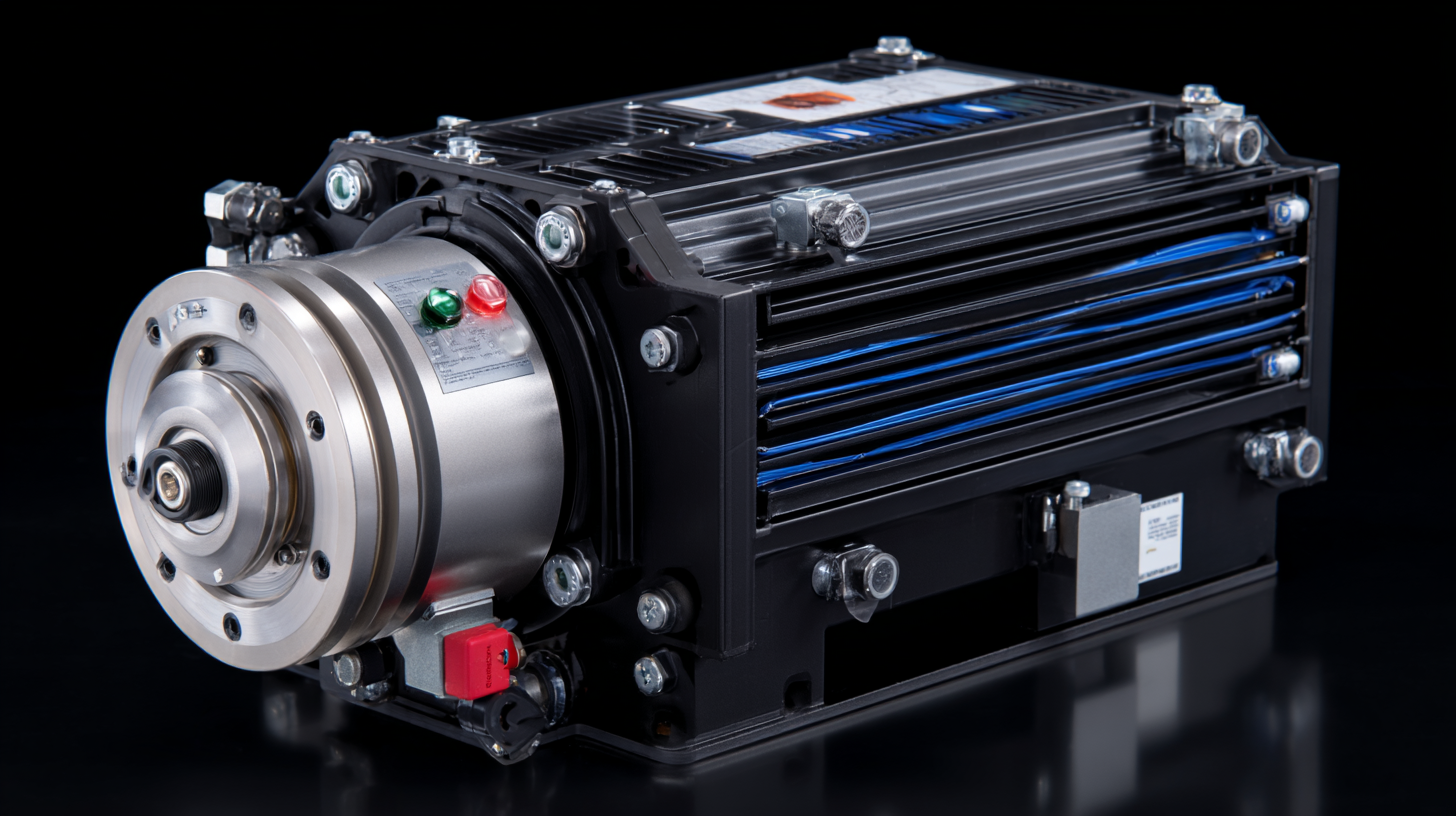

The integration of smart technologies into large brushless motors is transforming their operational efficiency and application versatility. By implementing advanced sensors and connectivity features, these motors can now provide real-time performance data, enabling predictive maintenance and reducing downtime. This not only enhances the longevity of the motors but also ensures that they consistently operate at optimal performance levels. For industries that rely heavily on precision and reliability, such as manufacturing and aerospace, this innovation is a game changer.

Tips: When selecting a brushless motor, consider models with built-in IoT capabilities, as they can significantly streamline monitoring processes. Additionally, ensure the motor's control system allows for easy interfacing with existing automation technologies to maximize integration benefits.

Moreover, smart technologies are paving the way for energy management enhancements within brushless motor systems. By utilizing algorithms that analyze energy consumption patterns, companies can adjust operations to minimize waste. This is particularly relevant in sectors focused on sustainability, allowing businesses to meet both operational goals and environmental standards.

Tips: Regularly update your motor's software to leverage the latest efficiency algorithms. Also, consider employing energy recovery techniques in your systems, which can further optimize energy use without compromising performance.