In the rapidly evolving landscape of modern automation technologies, the role of the BLDC (Brushless Direct Current) Servo Motor has become increasingly pivotal. This advanced motor type is celebrated for its ability to deliver high efficiency, precision, and reliability, making it an ideal choice for a wide range of applications, from industrial robotics to precision machining.

Understanding the operational principles and advantages of BLDC Servo Motors is crucial for engineers and designers seeking to optimize performance while reducing energy consumption and maintenance costs. This comprehensive guide aims to delve into the intricacies of how BLDC Servo Motors function, their key benefits over conventional motors, and the best practices for integrating them into automated systems. By exploring these aspects, we will equip professionals with the knowledge necessary to harness the full potential of BLDC Servo Motors, ensuring enhanced productivity and innovation in their automation endeavors.

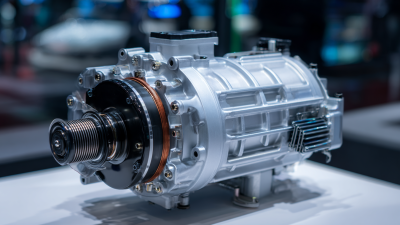

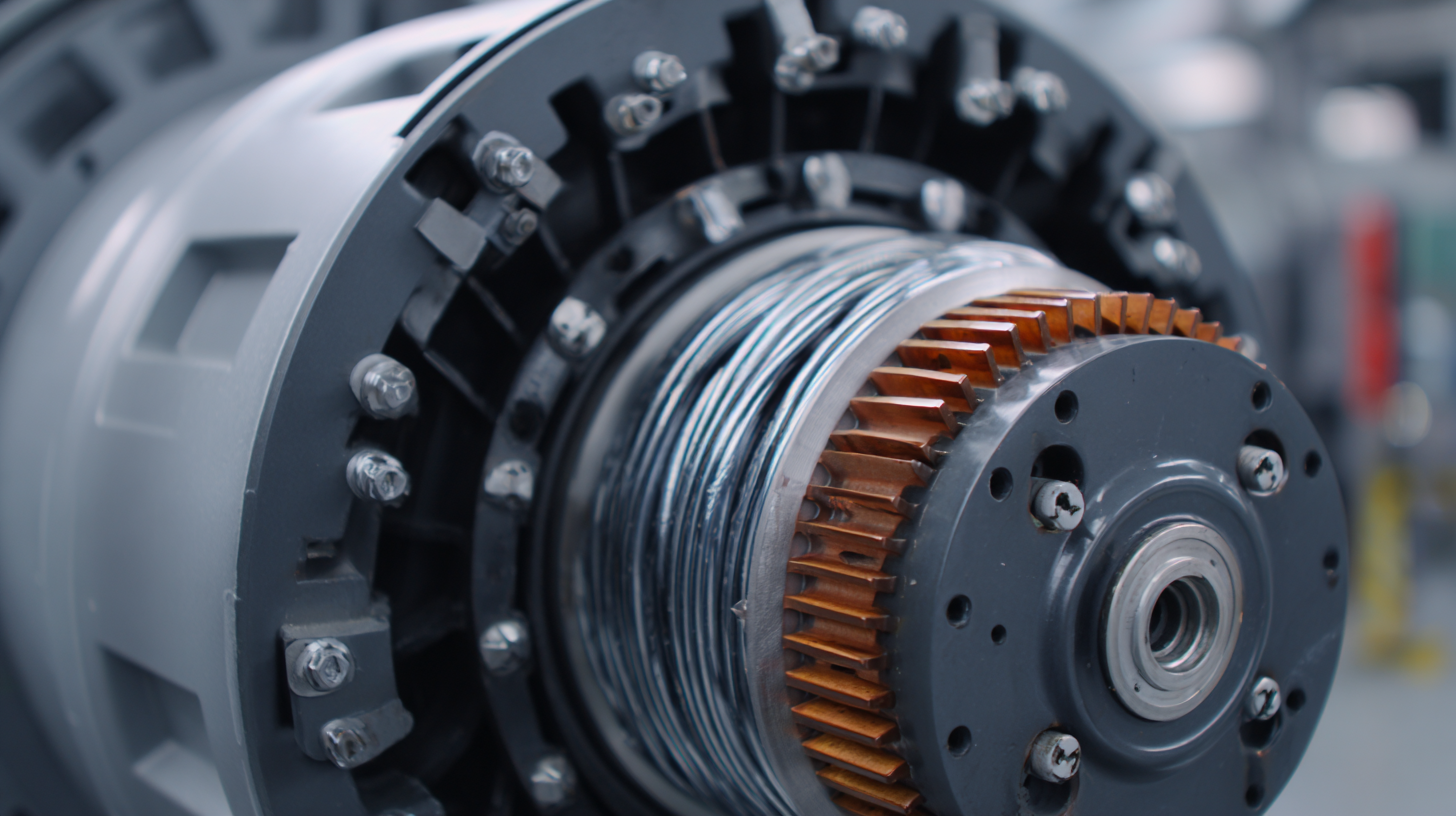

Brushless DC (BLDC) servo motors play a pivotal role in contemporary automation technologies, significantly enhancing efficiency and precision. These motors utilize a permanent magnet rotor and a stator with windings, eliminating the need for brushes, which are common in traditional DC motors. This design reduces friction and wear, resulting in a longer lifespan and lower maintenance costs. According to recent market analysis, the global brushless DC motor market is projected to grow substantially, driven by advancements in motion control systems and their integration into various industrial applications.

Brushless DC (BLDC) servo motors play a pivotal role in contemporary automation technologies, significantly enhancing efficiency and precision. These motors utilize a permanent magnet rotor and a stator with windings, eliminating the need for brushes, which are common in traditional DC motors. This design reduces friction and wear, resulting in a longer lifespan and lower maintenance costs. According to recent market analysis, the global brushless DC motor market is projected to grow substantially, driven by advancements in motion control systems and their integration into various industrial applications.

To fully grasp the capabilities of BLDC servo motors, one must understand the fundamental principles of motion control. Automation technologies increasingly rely on the precise positioning and speed control provided by these motors. As highlighted by industry insights, engineers must be equipped with knowledge of motion control fundamentals to leverage emerging technologies effectively. The demand for reliable and efficient motion control solutions in sectors such as robotics, manufacturing, and aerospace is on the rise, making the understanding of BLDC systems indispensable for forward-thinking professionals in the field.

Brushless DC (BLDC) servo motors are gaining traction in modern automation technologies due to their superior efficiency and performance compared to traditional brushed motors. According to a report by Markets and Markets, the global BLDC motor market is expected to grow from USD 19.8 billion in 2020 to USD 26.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.9%. This growth is primarily driven by the inherent advantages of BLDC servo motors, such as higher torque-to-weight ratios and greater durability, which are essential for applications in robotics, industrial automation, and precision engineering.

One of the most significant advantages of BLDC servo motors is their efficiency in converting electrical energy into mechanical energy. Reports indicate that BLDC motors can achieve efficiency rates of up to 90%, compared to only about 70-80% for traditional brushed motors. This increased efficiency translates into lower energy costs and reduced heat generation, allowing for longer operational lifetimes and less maintenance. In addition, the lack of brushes in BLDC motors significantly reduces wear and tear, resulting in improved reliability and performance in high-demand settings. As industries continue to seek more energy-efficient solutions, the shift towards BLDC servo motors over their traditional counterparts is expected to accelerate.

| Feature | BLDC Servo Motors | Traditional Motors |

|---|---|---|

| Efficiency | 90-95% | 70-85% |

| Torque-to-Weight Ratio | High | Moderate |

| Maintenance | Low | High |

| Control Precision | Very High | Moderate |

| Speed Range | Wide | Limited |

| Heat Generation | Low | High |

| Application Areas | Industrial automation, robotics, aerospace | General machinery, home appliances |

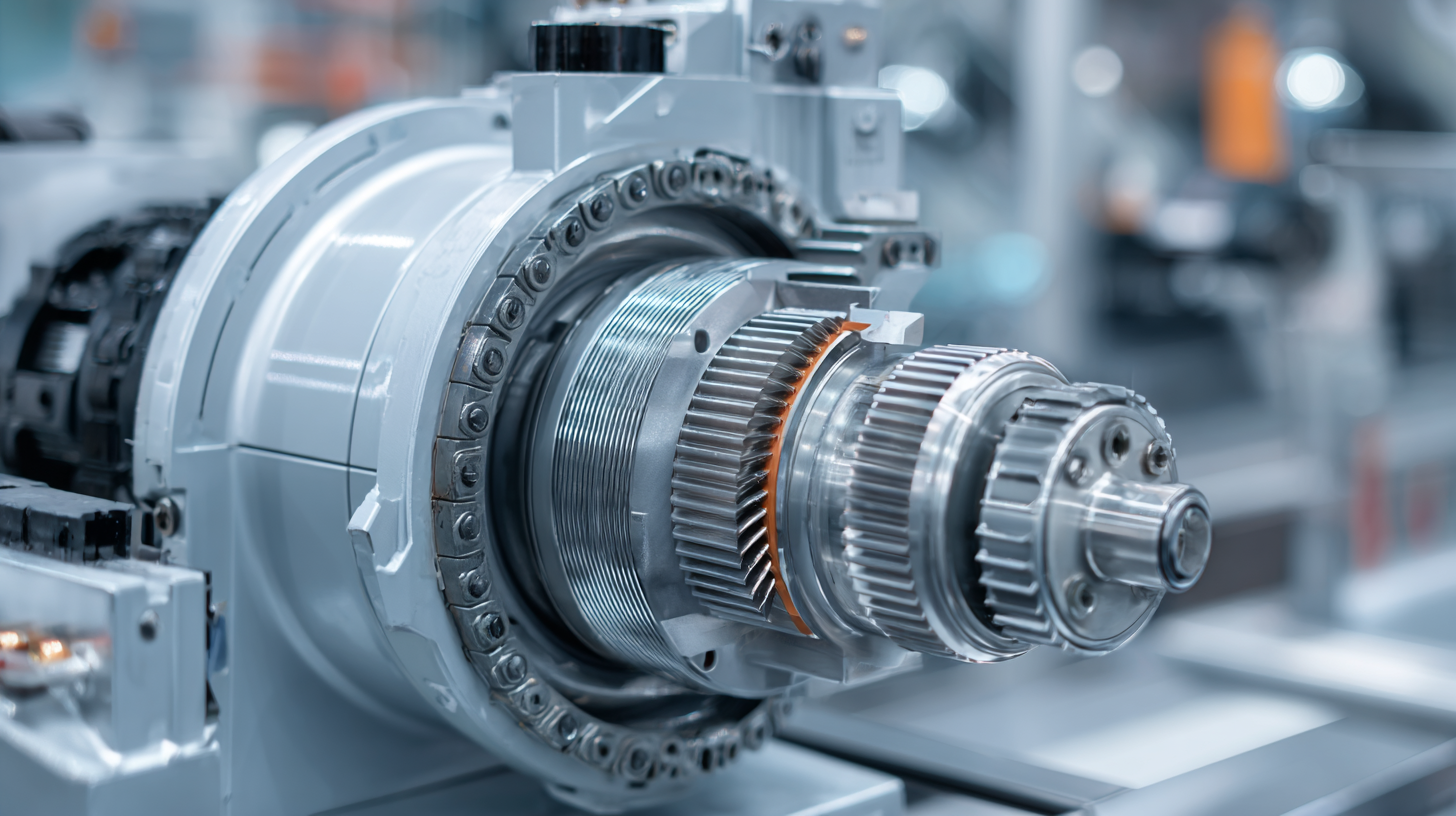

When selecting Brushless DC (BLDC) servo motors for modern automation technologies, there are several key parameters to consider. First and foremost is the motor's torque and speed ratings. According to a report by Research and Markets, the global BLDC motor market is expected to grow to USD 28.71 billion by 2027, with torque density being a critical factor for applications in robotics and aerospace. Higher torque ratings enable more efficient operation, particularly in applications requiring rapid acceleration and deceleration.

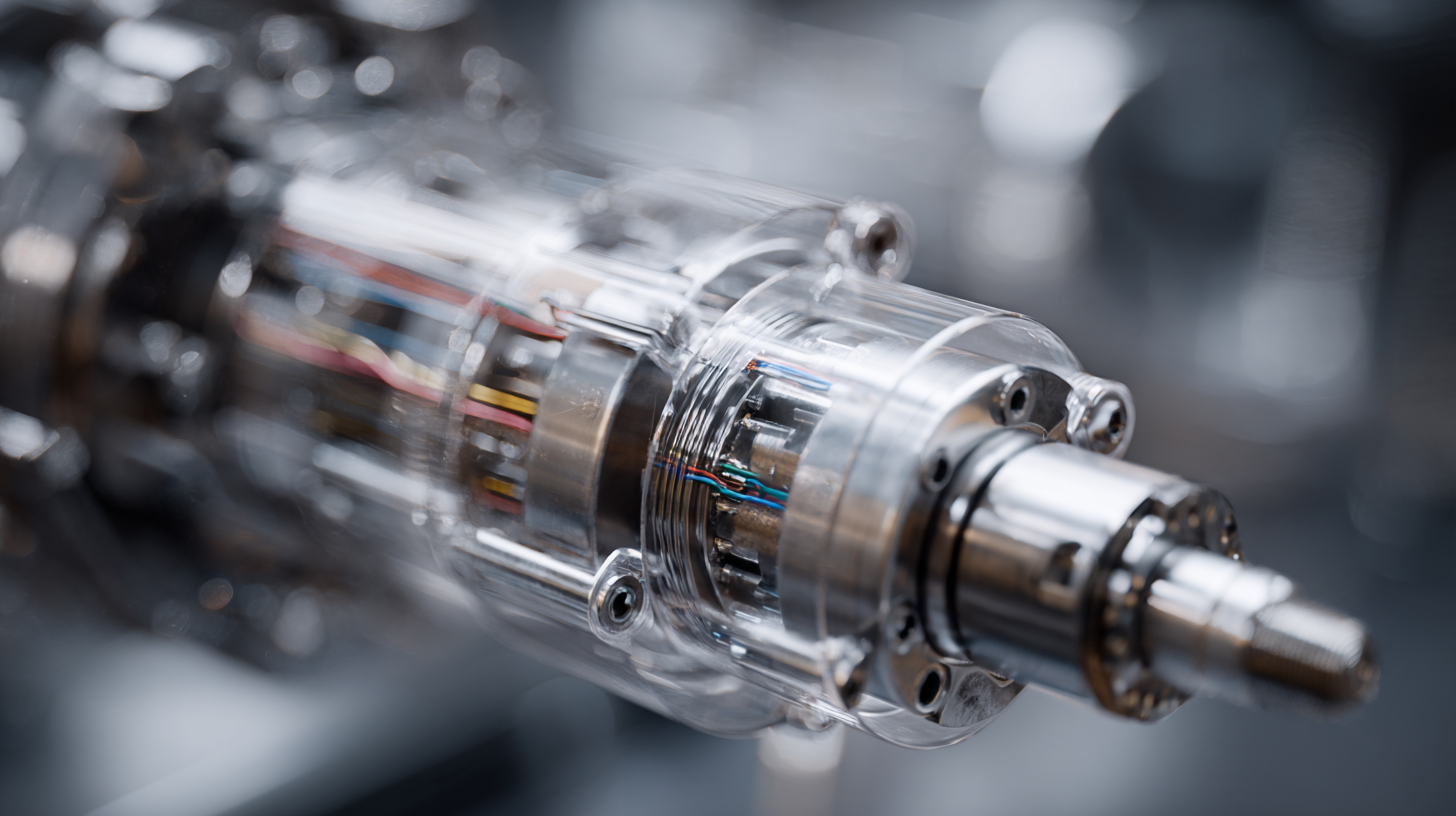

Another essential parameter is the motor's efficiency and thermal performance. The same report indicates that BLDC motors can achieve efficiency rates of 85% to 90%, significantly higher than those of traditional brushed motors. This is crucial in minimizing thermal losses and extending the motor’s operational life, especially under continuous load conditions. Additionally, considering the control system compatibility and the motor’s integration within existing automation frameworks is vital for optimizing performance and ensuring seamless operation across various applications.

Lastly, the sizing and weight of the motor should not be overlooked, as compact designs can facilitate easier installation and better performance in restricted spaces. As automation demands continue to ascend, selecting the right BLDC servo motor based on these parameters will be pivotal in enhancing operational efficiency and reliability across diverse industrial settings.

The implementation of Brushless Direct Current (BLDC) servo motors in industrial automation systems has gained remarkable prominence due to their efficiency and precision. These motors are characterized by a smooth torque profile and high speed control, making them ideal for applications requiring accurate positioning and rapid response times. In modern automation, manufacturers are increasingly adopting BLDC servo motors for tasks ranging from robotics to conveyor systems, where reliability and performance are paramount.

**Tips:** When selecting BLDC servo motors for your automation setup, consider factors such as the motor's size, torque requirements, and operational speed. Ensure that the controller not only supports the motor specifications but also integrates seamlessly with your existing systems. Regular maintenance checks will also prolong the lifespan of these motors and enhance overall system efficiency.

Moreover, the versatility of BLDC servo motors allows for their use across various environments. Their ability to function effectively at different temperatures and their low noise operation makes them suitable for both industrial and cleanroom settings. As automation technologies continue to evolve, the integration of BLDC servo motors will likely remain a crucial element in optimizing production processes and improving operational efficiency.

**Tips:** Always evaluate the motor's construction and cooling mechanisms for better performance in high-demand environments. Selecting the right encoder type can also help achieve better accuracy in positioning applications.

Maintaining BLDC servo motors is crucial for ensuring their optimal performance in automation systems. These motors are renowned for their efficiency and reliability, but they can still face issues if not properly cared for. Regular inspections are vital; check for signs of wear, secure connections, and proper alignment. Keeping the motor free of dust and contaminants can prevent overheating and ensure smooth operation.

**Tips:** Always lubricate the mechanical components according to the manufacturer's guidelines to reduce friction and extend the motor's lifespan. Implement a routine testing protocol to monitor performance parameters like temperature and vibration, which can help identify potential problems before they escalate.

Troubleshooting BLDC servo motors often involves examining the controller settings and feedback mechanisms. Many issues can stem from incorrect configuration or electrical faults. Ensure that the firmware is up-to-date and that calibration has been performed correctly. Electrical noise can also disrupt motor performance, so consider employing shielding techniques to enhance signal integrity.

**Tips:** When diagnosing faults, utilize diagnostic tools and software to analyze performance data. This not only aids in identifying issues but also assists in fine-tuning the motor for greater efficiency in automation applications.