When embarking on a project that requires a reliable power source, one of the most critical components to consider is the Brushless Electric Motor. These motors have gained immense popularity due to their efficiency, longevity, and low maintenance needs compared to their brushed counterparts.

However, selecting the right brushless electric motor can be a daunting task, given the array of options available on the market. Factors such as torque, speed, and application-specific requirements play vital roles in ensuring optimal performance and energy efficiency.

In this blog, we will guide you through the essential aspects of choosing the ideal brushless electric motor for your specific needs, enabling you to maximize the effectiveness of your project while minimizing energy consumption and operational costs. Understanding these criteria will empower you to make an informed decision that aligns with your project's goals.

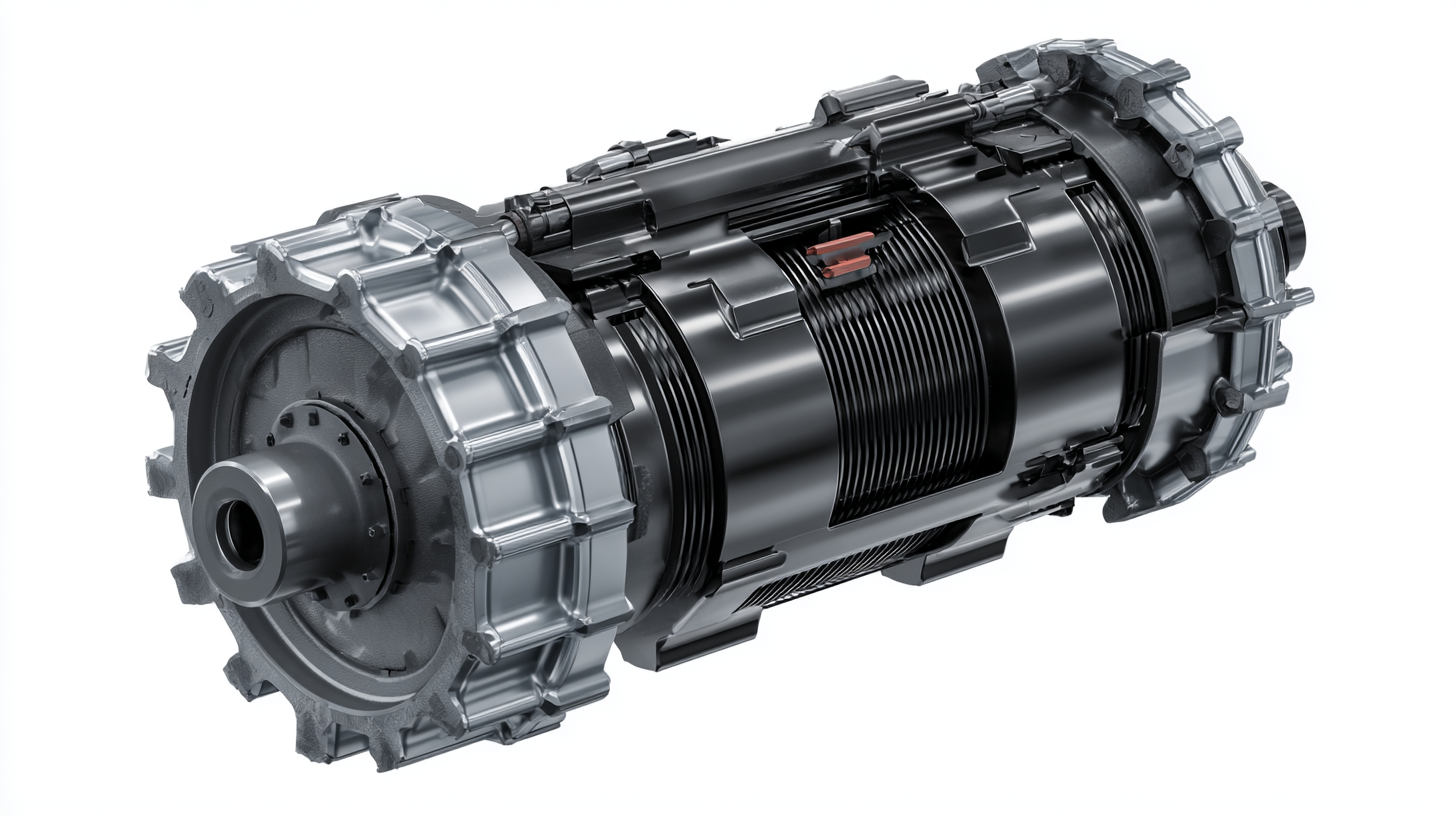

Brushless electric motors (BLDC) have gained significant traction in various industries due to their superior efficiency, longevity, and performance. Unlike traditional brushed motors, brushless models utilize electronic commutation, which eliminates the friction and energy loss associated with brushes. According to a report by the International Energy Agency, BLDC motors can achieve efficiencies of up to 90%, significantly reducing energy consumption and operational costs for businesses. Additionally, the absence of brushes allows for quieter operation and lower maintenance requirements, making them ideal for applications ranging from robotics to electric vehicles.

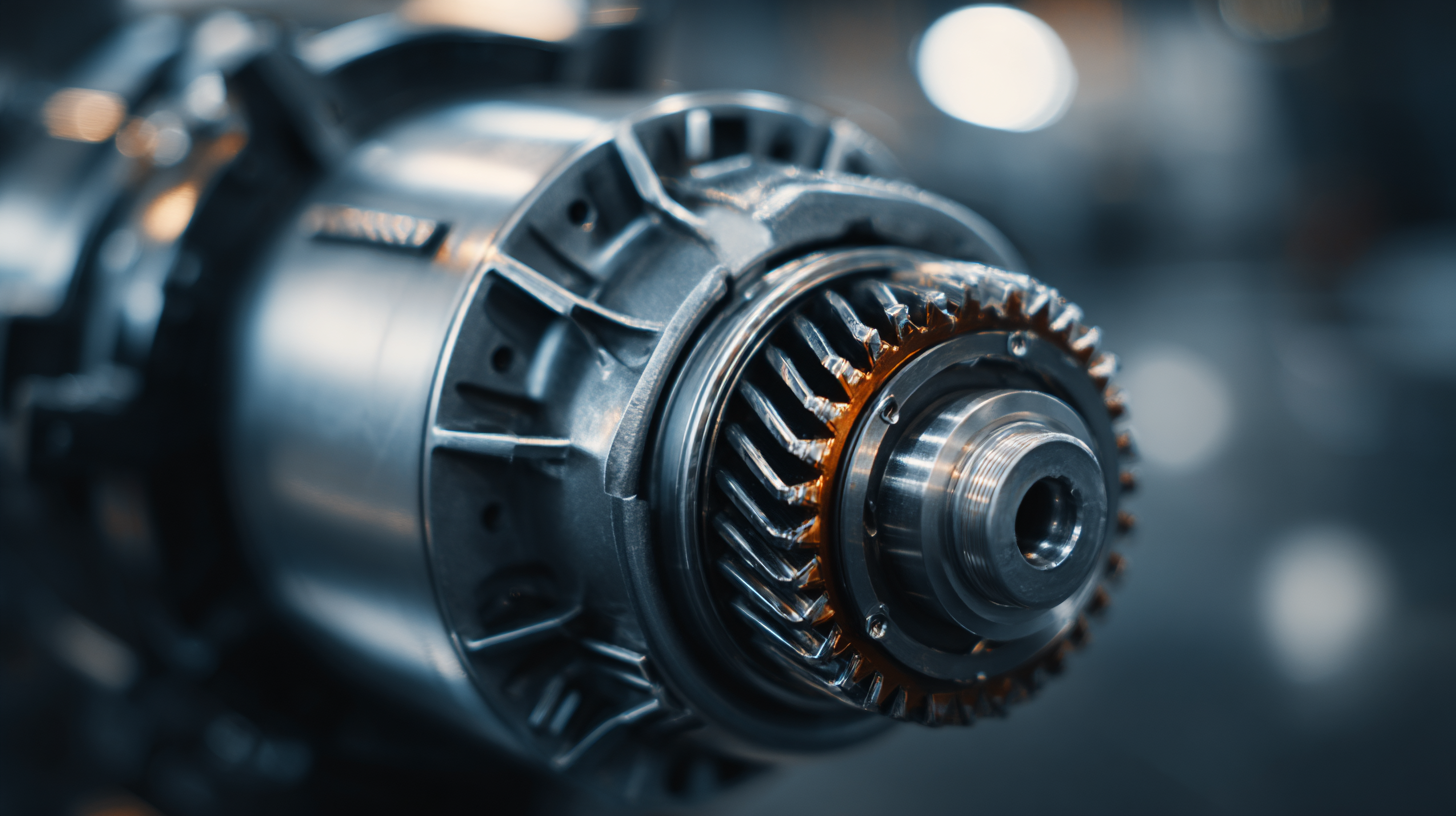

When selecting a brushless electric motor for your project, consider key features such as torque, speed, and thermal performance. For instance, a high torque-to-weight ratio can be crucial for applications requiring quick acceleration and responsiveness. Moreover, the temperature range in which the motor operates is vital, as overheating can lead to premature failure.

**Tip:** Always assess your project’s specific needs and compare motor specifications carefully before making a decision. Another helpful tip is to consider the motor's compatibility with your control system; this can greatly enhance the overall efficiency and performance of your setup. Opting for a motor with a built-in driver can streamline integration and reduce installation complexity.

When selecting a brushless electric motor for your project, assessing your requirements around power, size, and weight is crucial. First, consider the power needs of your application. Determine the maximum load the motor must handle and whether the operational duty cycle will necessitate peak power for short bursts or sustained output over time. Calculating torque and RPM can help guide your selection, ensuring the motor aligns with your project goals while maintaining optimal efficiency.

Next, size and weight must be addressed as they can significantly affect the overall design and performance of your project. A motor that is too large may be impractical, adding unnecessary weight and complicating integration. Conversely, an undersized motor could lead to efficiency losses and may not meet operational requirements. Evaluate the spatial constraints of your design to identify motors that fit comfortably while still offering sufficient power without compromising performance. Balancing these factors will enhance not only the efficiency of your project but also its overall effectiveness.

When selecting the right brushless electric motor for your project, understanding how to read specifications and performance ratings is crucial for ensuring optimal efficiency. Efficiency ratings often include parameters like efficiency percentage, torque-to-weight ratio, and max speed. Familiarize yourself with standard abbreviations such as RPM (revolutions per minute), Kt (torque constant), and Kv (velocity constant) to make sense of the motor's capabilities.

When selecting the right brushless electric motor for your project, understanding how to read specifications and performance ratings is crucial for ensuring optimal efficiency. Efficiency ratings often include parameters like efficiency percentage, torque-to-weight ratio, and max speed. Familiarize yourself with standard abbreviations such as RPM (revolutions per minute), Kt (torque constant), and Kv (velocity constant) to make sense of the motor's capabilities.

Tips for evaluating motor efficiency:

When selecting the right type of brushless electric motor, it's essential to compare the available options to ensure optimal performance for your project. Brushless motors, commonly categorized by their construction and operational characteristics, include both in-runner and out-runner designs. In-runner motors, featuring a rotor mounted inside the stator, are typically used in applications requiring high speed and efficiency. According to a report by Allied Market Research, the global brushless motor market is expected to grow at a CAGR of 6.2% from 2020 to 2027, indicating a rising preference for these motors in industries such as automotive and aerospace.

On the other hand, out-runner motors, which have their rotor outside, are favored for applications needing high torque at lower RPMs, making them ideal for robotics and drone technologies. Data from Research and Markets highlights that as of 2021, out-runner designs accounted for approximately 40% of the brushless motor market due to their superior torque capabilities. Ultimately, the choice between in-runner and out-runner brushless motors depends heavily on specific application requirements such as speed, torque, and efficiency, allowing engineers to tailor their projects for peak performance.

When selecting a brushless electric motor for your project, understanding the delicate balance between cost and performance is crucial. An analysis from Research and Markets indicates that the global brushless motor market is expected to reach $16 billion by 2025, growing at a CAGR of 10.5%. This growth reflects not only the increasing adoption of brushless motors in various applications but also the escalating demand for efficient, high-performance solutions that justify a higher investment.

Budgeting for quality means acknowledging that while cheaper alternatives may be tempting, they often fall short in efficiency and longevity. A study published by the Journal of Electrical Engineering found that high-quality brushless motors can improve energy efficiency by up to 25% compared to lower-grade options, significantly reducing operational costs over time. Additionally, investing in a reliable motor can minimize downtime and maintenance expenses, which are crucial for projects that require sustained performance and reliability. This underscores the importance of considering long-term gains over initial savings in the budgeting process for motor selection.