The selection of the right Brushless DC Servo Motor is critical in optimizing performance and efficiency across a wide range of applications from robotics to aerospace. According to a recent report by ResearchAndMarkets, the global servo motor market, which includes Brushless DC Servo Motors, is projected to reach USD 9.5 billion by 2025, growing at a CAGR of 7.1% from 2020. This growth underscores the increasing reliance on advanced motion control systems that utilize these sophisticated motors for precise speed and position control.

Understanding the key specifications, such as torque, speed, and feedback systems, is essential for engineers and designers to ensure compatibility with their specific applications. As the demand for automation and efficiency in industrial processes intensifies, the ability to choose the right Brushless DC Servo Motor becomes paramount in maintaining competitive advantage and achieving operational excellence.

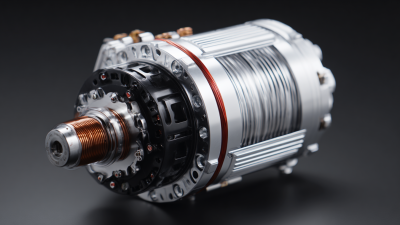

When developing a brushless motor controller from scratch with a Pico, it’s essential to understand the fundamentals of brushless DC (BLDC) motors and their applications. BLDC motors are widely used in various sectors, including e-bikes, where their efficiency and performance are critical. Unlike traditional brushed motors, brushless motors offer advantages like reduced friction, less maintenance, and improved longevity. They operate using an electromagnetic process that minimizes energy loss, making them the ideal choice for applications requiring precise motion control and responsiveness.

To create an effective motor controller, one must consider key factors such as the motor's voltage, current requirements, and control algorithm. The controller should harness PWM (Pulse Width Modulation) techniques to regulate the speed and torque of the motor accurately. Incorporating feedback mechanisms, such as encoders or Hall effect sensors, enhances the controller's performance, ensuring smooth operation and precise positioning. As the demand for efficient motion control grows, particularly in automation and electric mobility, understanding these foundational concepts becomes increasingly vital for engineers working in the field.

When selecting a brushless DC servo motor for your application, it’s essential to consider several key factors that greatly influence performance and efficiency.

Firstly, evaluate the motor's torque and speed requirements based on the demands of your specific application. Different tasks may necessitate varying levels of power and precision, which should align with the motor's specifications. Additionally, consider the operating environment; factors such as temperature fluctuations, humidity, and potential exposure to contaminants can affect the motor's longevity and reliability.

Tip: Always check the torque-to-weight ratio of the motor you are considering. A higher ratio typically indicates better performance for demanding applications, ensuring that the motor can maintain speed and precision even under load.

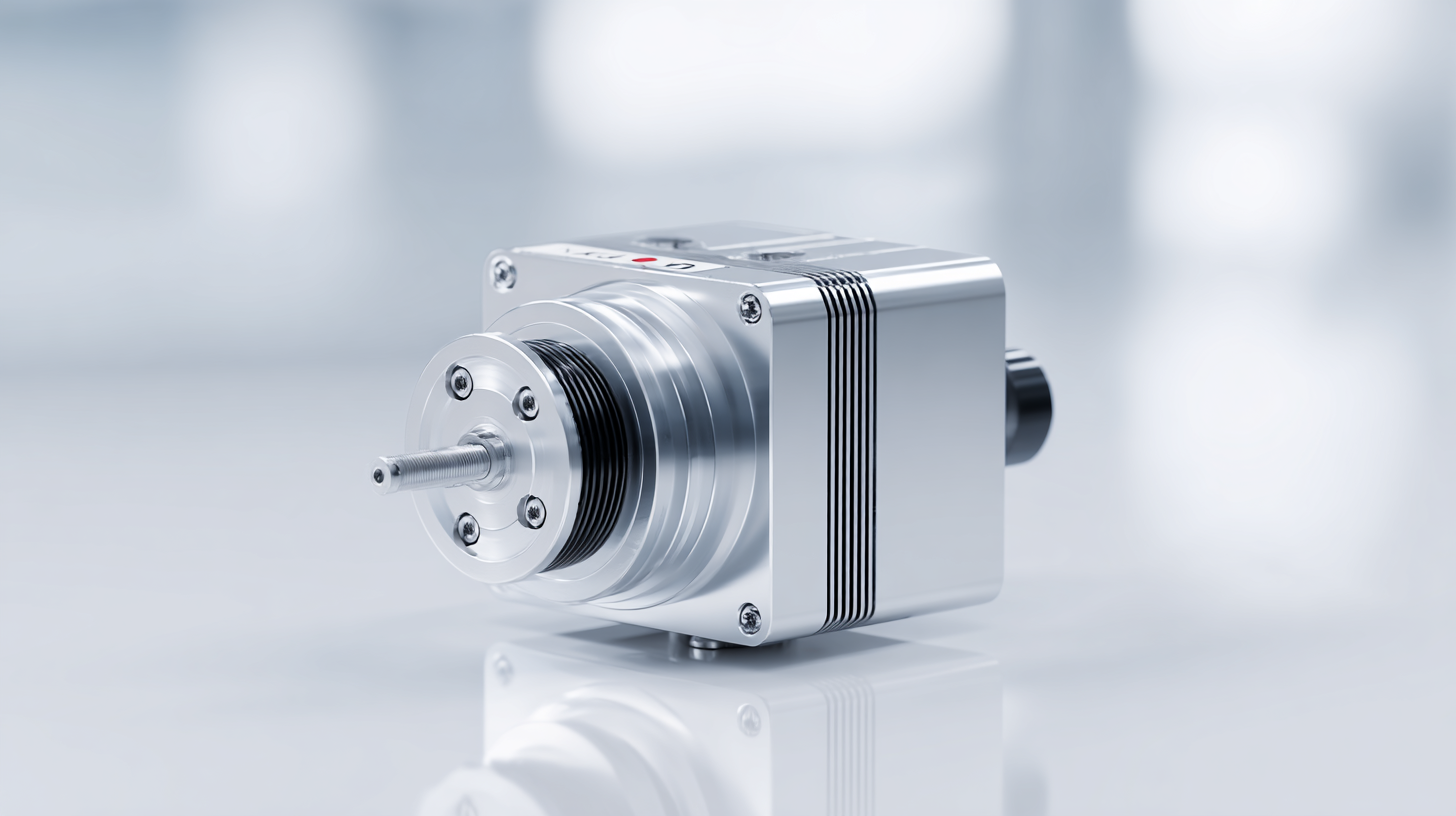

Another important factor is the feedback mechanism you choose, as this will significantly impact control accuracy. Options such as incremental encoders and absolute encoders offer varying levels of precision, so assess what best fits your need. Lastly, paying attention to the power supply requirements is crucial; ensure that your chosen motor integrates seamlessly with your existing systems to prevent any operational issues.

Tip: Review industry reports that project the industrial automation market growth, which is expected to increase from $205.86 billion in 2022 to $395.09 billion by 2029, reflecting a compound annual growth rate of 9.8%. Such data emphasizes the importance of investing in high-quality components like brushless DC servo motors to remain competitive.

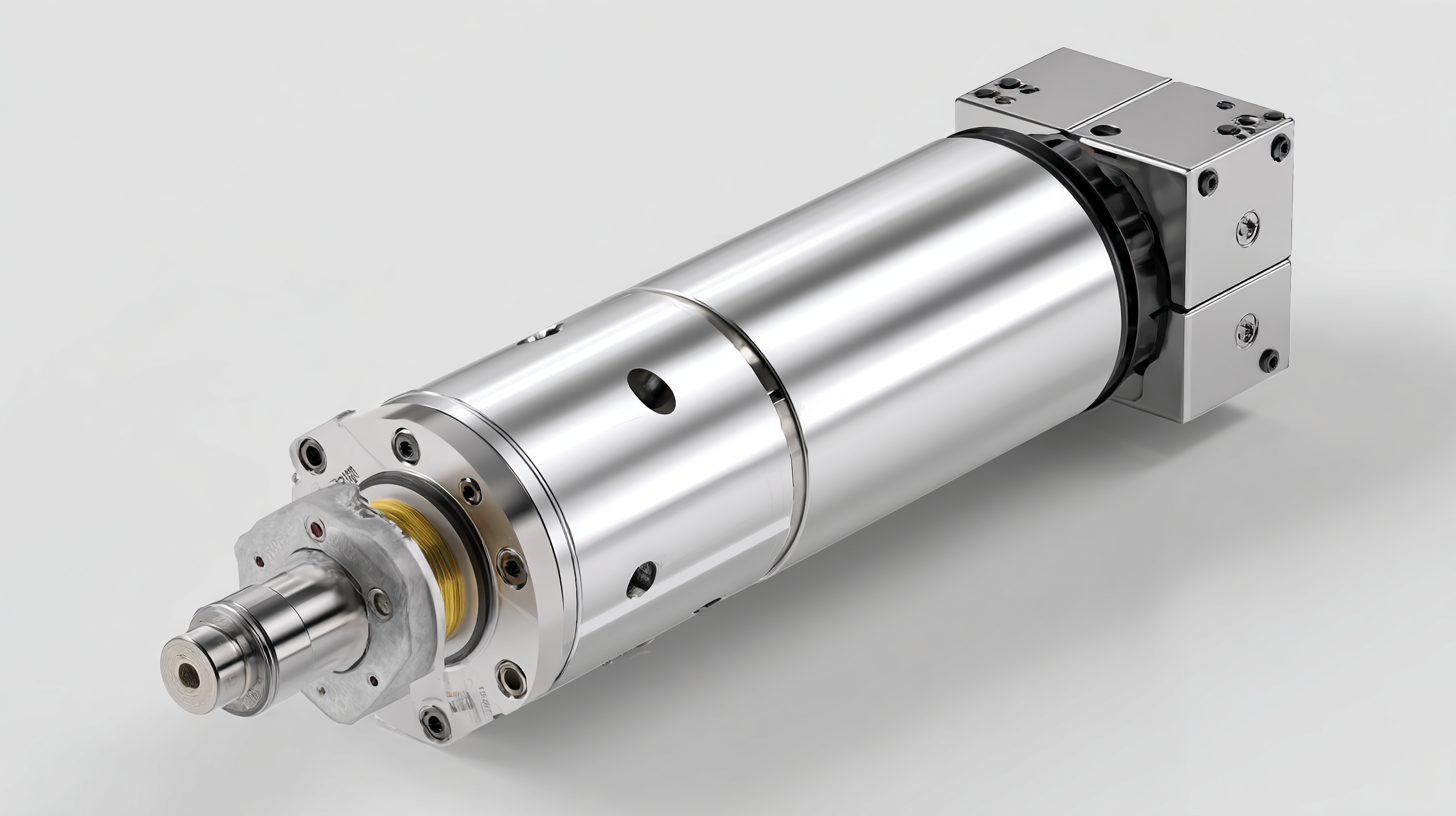

When selecting a brushless DC servo motor, understanding the torque and speed requirements of your application is crucial for achieving optimal performance. Torque is the motor's capability to perform work, and it is essential to assess the load characteristics and dynamic response needed during operation. For instance, applications that involve sudden starts or changes in direction, such as robotics and CNC machinery, require a motor with a high starting torque to ensure precise movement and control.

In parallel, evaluating speed requirements is equally important. The maximum speed at which a motor can operate directly affects its efficiency and operational capacity. Different applications may demand varying speeds; for example, conveyor systems often require consistent speed for material handling, whereas injection molding machinery may need high-speed cycles. By determining the required torque and speed, you can select a brushless DC servo motor that not only meets the application's immediate needs but also provides reliable performance and longevity under varying operational conditions.

When selecting the right brushless DC servo motor for your application, understanding control systems and compatibility is crucial. The servo motor's performance is intricately linked to its control system; a mismatch can lead to inefficiencies. According to a report by Allied Market Research, the global servo motor market is projected to reach $11.61 billion by 2026, underscoring the increasing demand for efficient control systems. To ensure compatibility, assess the communication protocols supported by the servo drive and confirm they align with your current setup, whether it utilizes CANopen, EtherCAT, or another system.

Tips: Always verify the feedback type required by the servo motor, such as incremental or absolute encoders, to match the demands of your application. Additionally, consider the required bandwidth – higher performance applications may need a control system capable of handling rapid response times.

Moreover, evaluate the motor's compatibility with existing hardware and software. A research study from MarketsandMarkets highlights that 40% of engineers choose servo systems based on interoperability with current technologies. Ensuring that the servo motor integrates smoothly with your existing control systems can lead to enhanced functionality and streamlined operations.

This bar chart compares the performance of four different brushless DC servo motors based on their torque and speed specifications. Choosing the right motor depends on understanding the requirements of your specific application.

When selecting a brushless DC servo motor for your application, budget considerations play a crucial role in ensuring cost-effectiveness without compromising on performance. One effective strategy is to assess your specific needs and match them with a motor that provides the essential features you require. For instance, if your application does not demand high precision or speed, you might explore entry-level options that offer reliability at a reduced cost. Manufacturers often provide a range of models that strike a balance between performance and affordability, making it easier to find a fitting choice without overspending.

It's also important to consider the total cost of ownership, which includes not just the initial purchase price, but also maintenance, energy consumption, and potential downtime costs. Investing in a slightly more expensive motor with higher efficiency and longer lifespan can yield savings in the long run. Additionally, look for models that come with robust warranties or customer support, as this can mitigate potential expenses related to repairs or replacements. By examining these factors closely, you can identify cost-effective brushless DC motors that align with both your budget and operational requirements.