The evolution of automation systems has led to significant advancements in motor control technologies, particularly with the rise of Brushless DC Motor Control. Industry reports highlight that the global brushless motor market is expected to reach USD 40 billion by 2026, growing at a CAGR of 9.6% from 2021 to 2026. This remarkable growth underscores the pivotal role that Brushless DC Motor Control plays in enhancing efficiency, reliability, and performance across various applications, including robotics, electric vehicles, and industrial automation. Companies are increasingly turning to brushless motors due to their superior characteristics, such as higher efficiency and torque density compared to traditional brushed motors. As a result, understanding the advantages of Brushless DC Motor Control in modern automation systems becomes essential for businesses aiming to leverage cutting-edge technology to stay competitive in an ever-evolving market landscape.

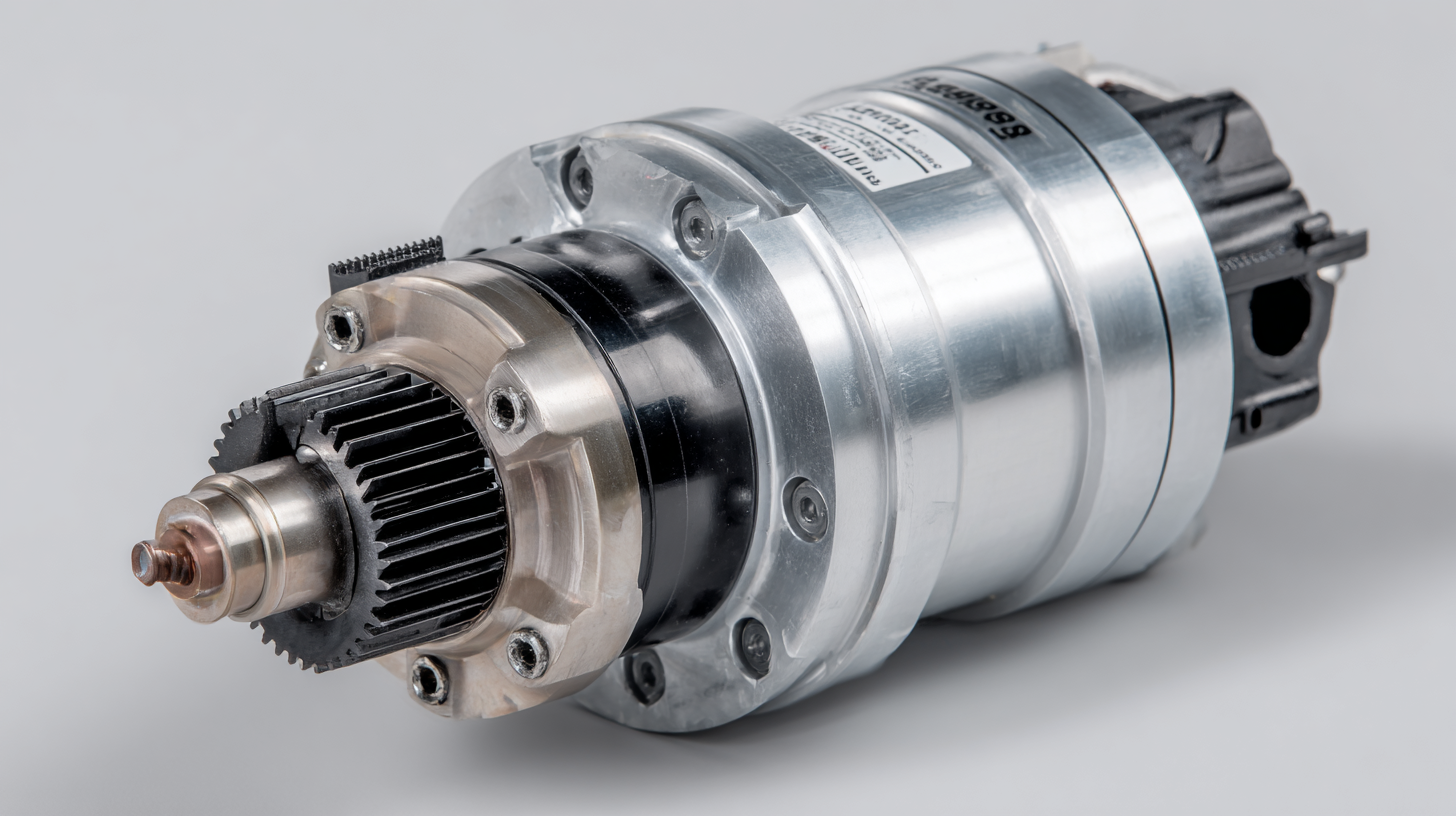

Brushless DC (BLDC) motors are increasingly recognized for their critical role in industrial automation applications, offering numerous advantages over traditional brushed motors. One of the primary benefits is their increased efficiency. According to a report by MarketsandMarkets, the global market for BLDC motors is projected to reach $35.1 billion by 2025, driven largely by the demand for energy-efficient technologies. BLDC motors can achieve efficiencies of over 90%, significantly reducing energy consumption and operational costs for manufacturers.

Furthermore, BLDC motors boast a longer operational lifespan due to their lack of brushes, which reduces wear and tear. This longevity translates into lower maintenance requirements, allowing industries to minimize downtime. A study from ResearchAndMarkets indicates that the maintenance costs for industrial automation systems can decrease by up to 30% with the implementation of BLDC technology. Additionally, the precise control over speed and torque offered by BLDC motors enhances overall system performance, making them ideal for tasks requiring high reliability and accuracy, such as robotics and conveyor systems. With these benefits, it's no wonder that BLDC motors are becoming a preferred choice in modern automation systems.

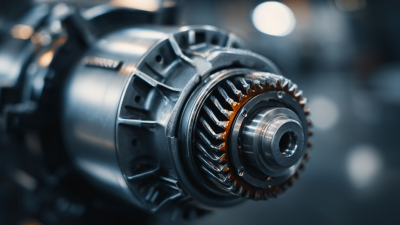

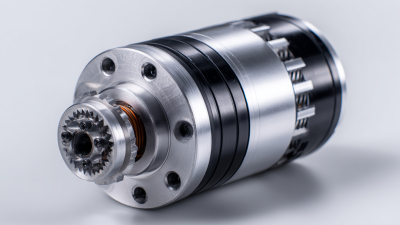

When comparing brushed and brushless DC motors, one of the most significant advantages of brushless motors is their superior efficiency, which directly impacts performance in automation systems. Brushless DC motors operate without the friction and wear associated with brushes, leading to reduced energy losses and improved thermal management. This inherent efficiency translates into higher power-to-weight ratios, allowing for more compact designs without sacrificing performance. As a result, systems utilizing brushless motors can operate longer and more reliably, making them ideal for demanding automation applications.

Furthermore, brushless motors offer greater control over speed and torque, enhancing their suitability for variable load conditions often found in modern automation environments. The precise electronic commutation of brushless motors enables smoother operation and quick response times, essential for applications requiring rapid changes in speed or direction. In contrast, brushed motors can suffer from performance degradation over time due to wear and maintenance needs, which can introduce variability in operational efficiency. Therefore, for optimized automation performance and longevity, brushless DC motors stand out as the preferred choice in contemporary industrial settings.

In high-demand environments, the longevity and reliability of brushless DC motors (BLDC) make them an indispensable choice for modern automation systems. Unlike their brushed counterparts, brushless motors eliminate friction and wear associated with brushes, resulting in significantly longer operational lifespans. According to a report by Allied Market Research, the global brushless DC motor market is projected to reach $19.59 billion by 2027, highlighting the increasing reliance on these motors due to their durability in challenging applications.

In high-demand environments, the longevity and reliability of brushless DC motors (BLDC) make them an indispensable choice for modern automation systems. Unlike their brushed counterparts, brushless motors eliminate friction and wear associated with brushes, resulting in significantly longer operational lifespans. According to a report by Allied Market Research, the global brushless DC motor market is projected to reach $19.59 billion by 2027, highlighting the increasing reliance on these motors due to their durability in challenging applications.

Additionally, brushless motors are designed to operate efficiently over extended periods, maintaining high performance even under stress. A study published in the Journal of Electrical Engineering and Automation demonstrated that BLDC motors can have a mean time between failures (MTBF) of over 20,000 hours, compared to approximately 3,000-5,000 hours for traditional brushed motors. This reliability translates to reduced maintenance costs and downtime, essential factors for industries that require consistent and efficient operation, such as manufacturing and robotics. The efficiency of brushless motors also contributes to lower heat generation, further enhancing their longevity and making them a cost-effective solution in demanding environments.

The implementation of brushless DC motors in modern automation systems brings significant energy consumption and cost-saving advantages. Unlike traditional brushed motors, brushless motors eliminate mechanical wear and friction, resulting in higher efficiency rates. This increased efficiency translates into lower energy costs, making them an attractive option for businesses looking to reduce operational expenses. Additionally, the longevity of brushless motors means less frequent replacements, further decreasing long-term costs associated with maintenance and downtime.

Moreover, in industrial applications where energy efficiency is paramount, brushless DC motors can significantly contribute to sustainability goals. With their ability to operate at optimal performance levels with reduced power requirements, these motors help decrease the overall carbon footprint of automation systems. Organizations that invest in brushless technology can not only achieve substantial savings on energy bills but also position themselves as environmentally responsible entities, benefiting from both financial and reputational advantages in an increasingly eco-conscious market.

This chart illustrates the energy consumption and cost savings associated with implementing brushless DC motor technology compared to traditional brushed DC motors. The data shows significant improvements in efficiency and cost-effectiveness when utilizing brushless technology in automation systems.

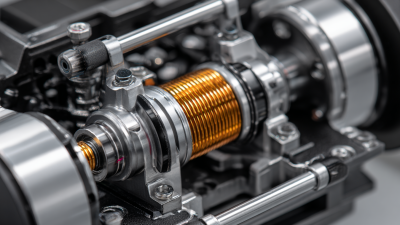

Brushless DC motors have revolutionized modern automation systems by offering enhanced efficiency, reliability, and lower maintenance requirements. Advanced control techniques, such as Field Oriented Control (FOC) and Direct Torque Control (DTC), have emerged, significantly improving the functionality and precision of brushless motors. According to a report by ResearchAndMarkets, the global brushless DC motor market is projected to reach approximately $20 billion by 2025, demonstrating the growing demand for these advanced control methods.

Field Oriented Control allows for precise torque and speed control by aligning the motor's magnetic field with the rotor's position. This technique not only maximizes performance but also reduces energy consumption, making it a preferred choice in industrial applications. Additionally, Direct Torque Control enhances response times and provides smooth operation under varying loads. As reported by Allied Market Research, the increasing automation in industries is a major catalyst for the adoption of such advanced control methods.

**Tips:** To optimize brushless motor performance, ensure that the control algorithms are correctly tuned to match the specific application requirements. Regular maintenance checks and updates to the control software can further enhance efficiency and prolong motor life. Consider integrating real-time monitoring tools to track performance metrics and make informed adjustments as needed.

| Feature | Description | Advantages | Applications |

|---|---|---|---|

| High Efficiency | Brushless DC motors convert electrical energy to mechanical energy more efficiently than brushed motors. | Reduced energy consumption and operating costs. | Robotics, HVAC systems, and electric vehicles. |

| Longevity | Lacks brushes which reduces wear and tear. | Longer lifespan and less maintenance. | Industrial machinery and consumer electronics. |

| Precision Control | Advanced control algorithms allow for fine-tuning operation. | Improved performance and accuracy. | Medical devices, CNC machines, and automation. |

| Compact Design | Smaller physical footprint compared to traditional motors. | Ideal for tight spaces and portable applications. | Drones, handheld tools, and compact appliances. |

| Quiet Operation | Minimal noise generation during operation. | Enhanced user comfort and ease of use. | Home appliances and office equipment. |