In recent years, Bldc Electric Motors have emerged as a cornerstone technology in enhancing energy efficiency across various modern applications. According to a market report by Allied Market Research, the global Bldc motor market is projected to reach $23.3 billion by 2027, demonstrating a CAGR of 8.5% from 2020 to 2027. This paradigm shift is largely driven by the motors' ability to provide optimal performance with reduced energy consumption, making them ideal for electric vehicles, home appliances, and industrial applications.

In recent years, Bldc Electric Motors have emerged as a cornerstone technology in enhancing energy efficiency across various modern applications. According to a market report by Allied Market Research, the global Bldc motor market is projected to reach $23.3 billion by 2027, demonstrating a CAGR of 8.5% from 2020 to 2027. This paradigm shift is largely driven by the motors' ability to provide optimal performance with reduced energy consumption, making them ideal for electric vehicles, home appliances, and industrial applications.

With efficiencies often exceeding 90%, Bldc Electric Motors can significantly cut energy costs while contributing to sustainability efforts. Their compact design and lower maintenance requirements further solidify their position in an increasingly eco-conscious market. As industries continuously seek ways to reduce their carbon footprint, the adoption of Bldc Electric Motors is set to play a critical role in the future of energy efficiency.

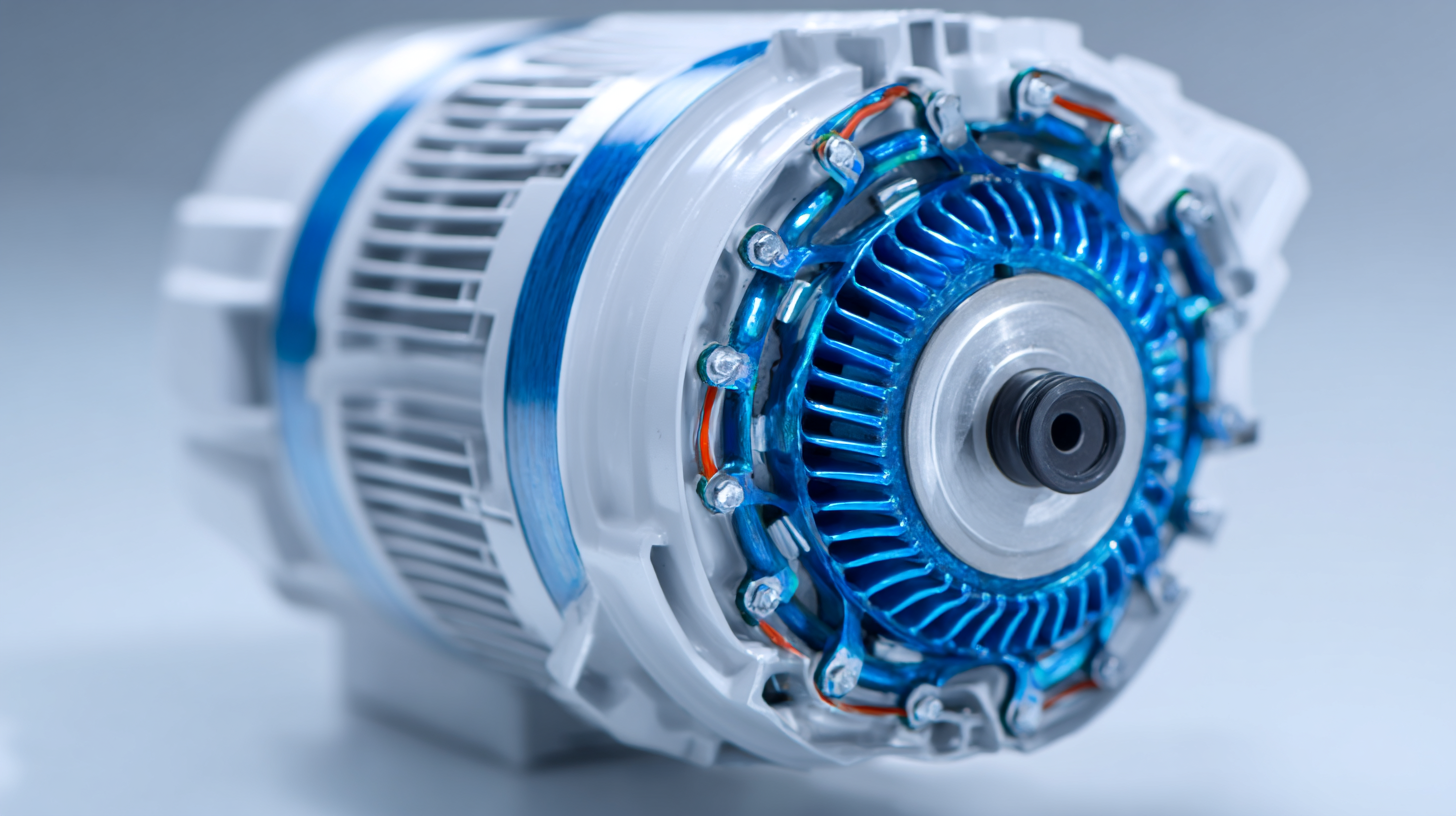

BLDC (Brushless Direct Current) motors are gaining momentum in modern applications due to their remarkable energy efficiency and innovative design. One of the key advantages of BLDC motors over traditional electric motors is their higher efficiency. Unlike brushed motors, which lose energy through friction and heat generated by brushes, BLDC motors utilize electronic commutation, resulting in less energy wasted. This efficiency not only reduces electricity consumption but also contributes to lower operational costs—making BLDC motors an attractive investment for businesses.

Another significant benefit is their longevity and reliability. Without brushes to wear down, BLDC motors have a longer lifespan and require less maintenance. This translates into fewer downtimes and lower replacement costs. Additionally, their compact size and lightweight nature open up new avenues for applications in industries ranging from automotive to consumer electronics.

**Tip:** When considering a switch to BLDC motors, assess your application needs carefully. Look for motors that match your specific torque requirements, and consider implementing a controller that optimizes performance across varying load conditions. This can further enhance the efficiency gains you experience with these advanced motors.

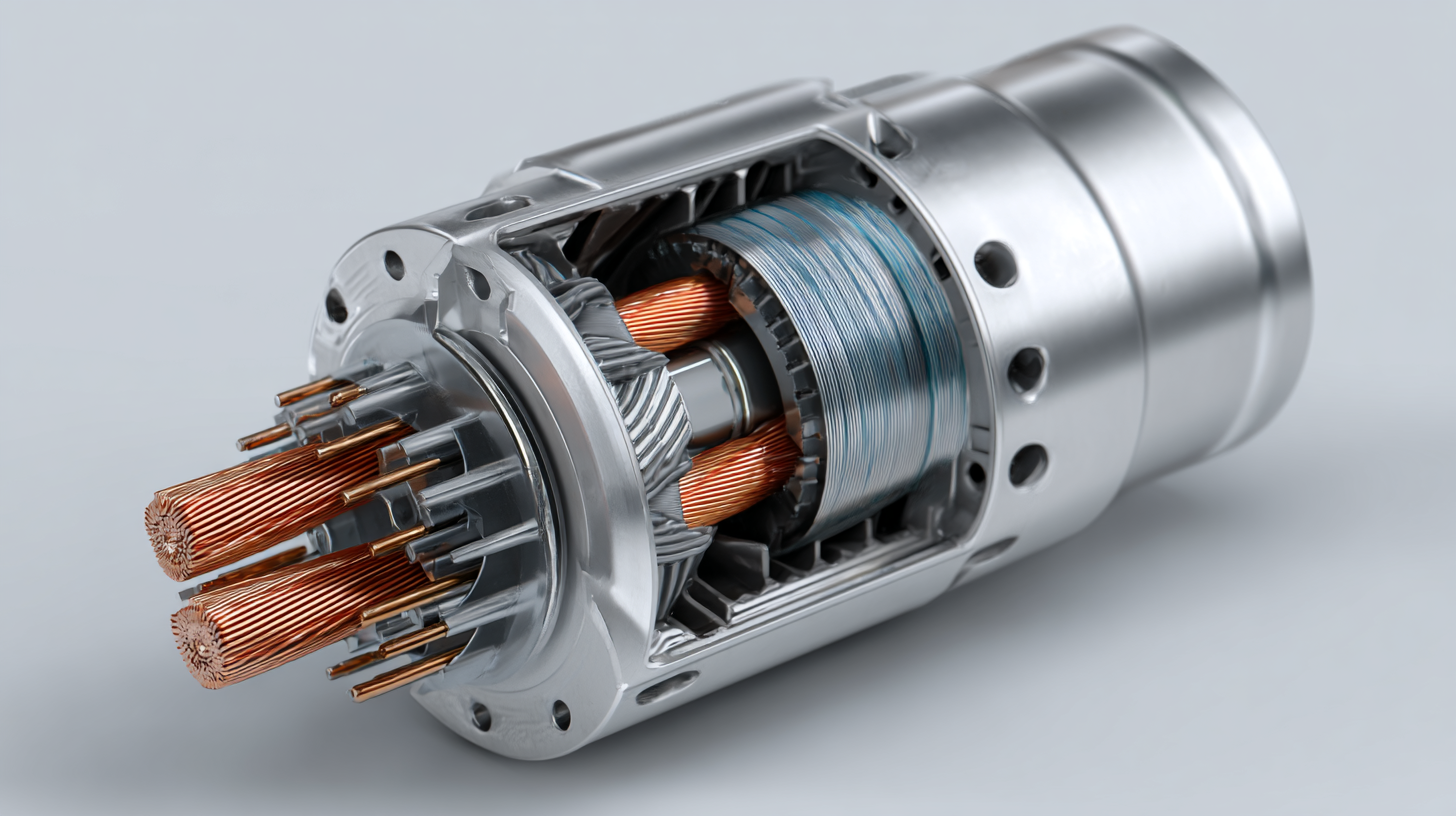

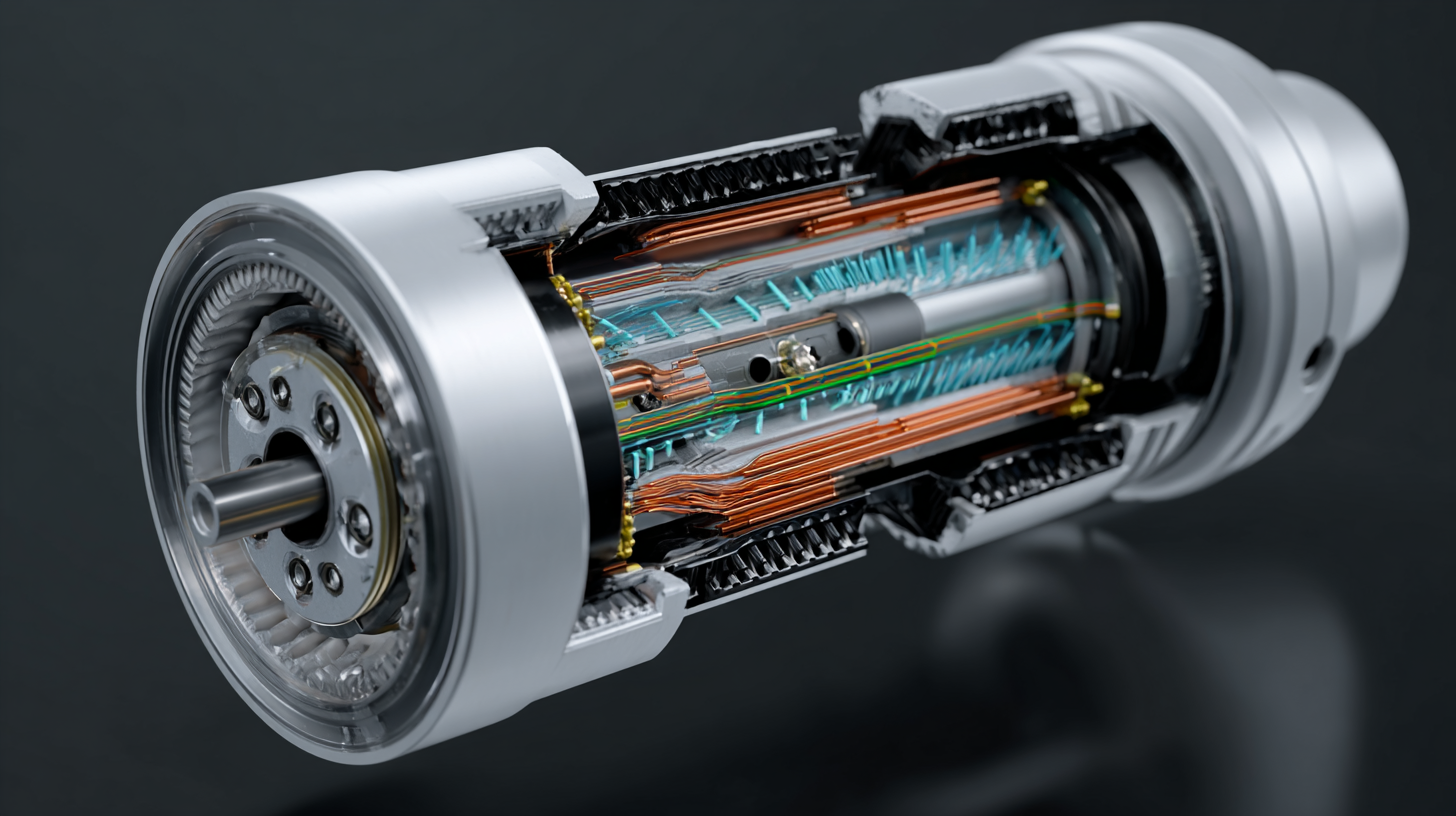

The rise of Brushless DC (BLDC) electric motors has significantly transformed various industries by enhancing energy efficiency and operational performance. In the automotive sector, for instance, BLDC motors contribute to the increased range and reduced energy consumption of electric vehicles (EVs). According to a report by the International Energy Agency (IEA), electric motors account for around 45% of global electricity consumption—emphasizing the need for efficiency improvements. BLDC technology allows for up to 90% efficiency in converting electrical energy into mechanical power, making them a crucial component in modern electric drive systems.

In the realm of home appliances, BLDC motors are redefining energy use. Devices like ceiling fans and refrigerators equipped with BLDC motors have been shown to consume up to 50% less energy compared to traditional motors. The U.S. Department of Energy has reported that advancements in motor technology could lead to annual savings of over $16 billion in energy costs by 2030.

**Tip:** When considering appliances or devices, manufacturers often provide energy efficiency ratings. Look for those that specifically mention the use of BLDC technology to maximize savings.

Furthermore, the industrial sector is benefiting, particularly in automation and robotics, where precision and energy performance are paramount. Data from the International Federation of Robotics indicates that the integration of BLDC motors in robotic systems can reduce operational costs by 20%, showcasing their essential role in promoting sustainability.

**Tip:** For businesses, investing in machinery that utilizes BLDC technology can translate into significant long-term savings and reduced carbon footprints.

Brushless DC (BLDC) motors are significantly enhancing energy efficiency in modern applications, leading to reduced operational costs for businesses. These motors operate without brushes, which means less friction, lower wear and tear, and efficient energy conversion. As a result, BLDC motors can achieve higher performance levels while consuming less power compared to traditional motors. This efficiency is critical as energy costs continue to rise globally, and companies seek innovative solutions to minimize expenses.

In addition to cost savings, the adoption of power-efficient technologies in government buildings is becoming mandatory, driving the demand for BLDC motors. This push for 5-star rated air conditioning systems and efficiency-focused fans not only helps in curbing electricity bills but also aligns with global sustainability goals.

**Tips for Selecting Energy-Efficient BLDC Motors:**

1. Look for motors with high efficiency ratings to ensure optimal performance and minimal energy loss.

2. Consider the specific application needs, such as torque requirements and speed, to select the right BLDC motor that fits your requirements.

3. Evaluate integration capabilities to ensure that the motor can seamlessly work with existing systems or applications.

| Application | Efficiency (%) | Cost Savings ($/year) | Environmental Impact (CO2 reduction in tons/year) |

|---|---|---|---|

| Electric Vehicles | 90% | 1500 | 2.5 |

| Home Appliances | 85% | 200 | 0.4 |

| Industrial Pumps | 95% | 3000 | 5.0 |

| Renewable Energy Systems | 92% | 2500 | 4.0 |

| HVAC Systems | 87% | 600 | 1.0 |

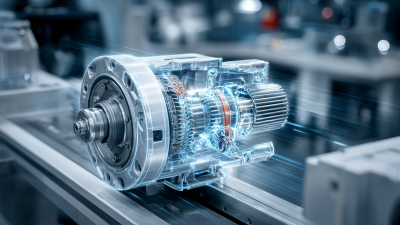

The advancements in Brushless Direct Current (BLDC) motor design are pivotal to enhancing energy efficiency across various modern applications, including electric vehicles and industrial automation. According to a report by the International Energy Agency, electric motors account for more than 40% of global electricity consumption, indicating a significant opportunity for efficiency improvements. Innovations such as new magnetic materials and advanced control algorithms have enabled BLDC motors to achieve efficiencies exceeding 90%, compared to traditional brushed motors which typically reach only around 70%.

Moreover, the integration of smart technology in BLDC motors has transformed manufacturing processes. With the advent of Industry 4.0, companies are adopting IoT-enabled motors that can communicate real-time data, enabling predictive maintenance and reducing downtime. A market analysis by Research and Markets projects that the global BLDC motor market will grow at a CAGR of 9.5% from 2021 to 2026, driven by these technological advancements. This growth is a testament to how innovation in BLDC motor design is not only improving energy efficiency but also redefining operational capabilities in numerous sectors.

Brushless Direct Current (BLDC) motors are at the forefront of revolutionizing energy efficiency, with significant implications for environmental sustainability. Unlike their traditional counterparts, BLDC motors operate without brushes, which minimizes friction and wear. This technology not only enhances the lifespan of the motor but also translates to reduced energy consumption. By optimizing power use, these motors have become essential in various applications, from electric vehicles to renewable energy systems, significantly lowering carbon footprints.

The environmental benefits of BLDC motors extend beyond their energy efficiency. They often utilize lighter materials and advanced designs that lead to decreased resource consumption during manufacturing. Furthermore, the extended lifespan and reduced maintenance requirements of BLDC motors result in less waste, making them a more sustainable choice in the long run. As industries increasingly focus on sustainability, the adoption of BLDC technology represents a shift towards greener solutions that align with global efforts to combat climate change and reduce pollution.

This chart illustrates the energy efficiency of Brushless Direct Current (BLDC) motors compared to traditional electric motors. As shown, BLDC motors achieve an efficiency rating of 90%, significantly outperforming the 70% efficiency typical of traditional motors. This higher efficiency translates to lower energy consumption and reduced environmental impact.