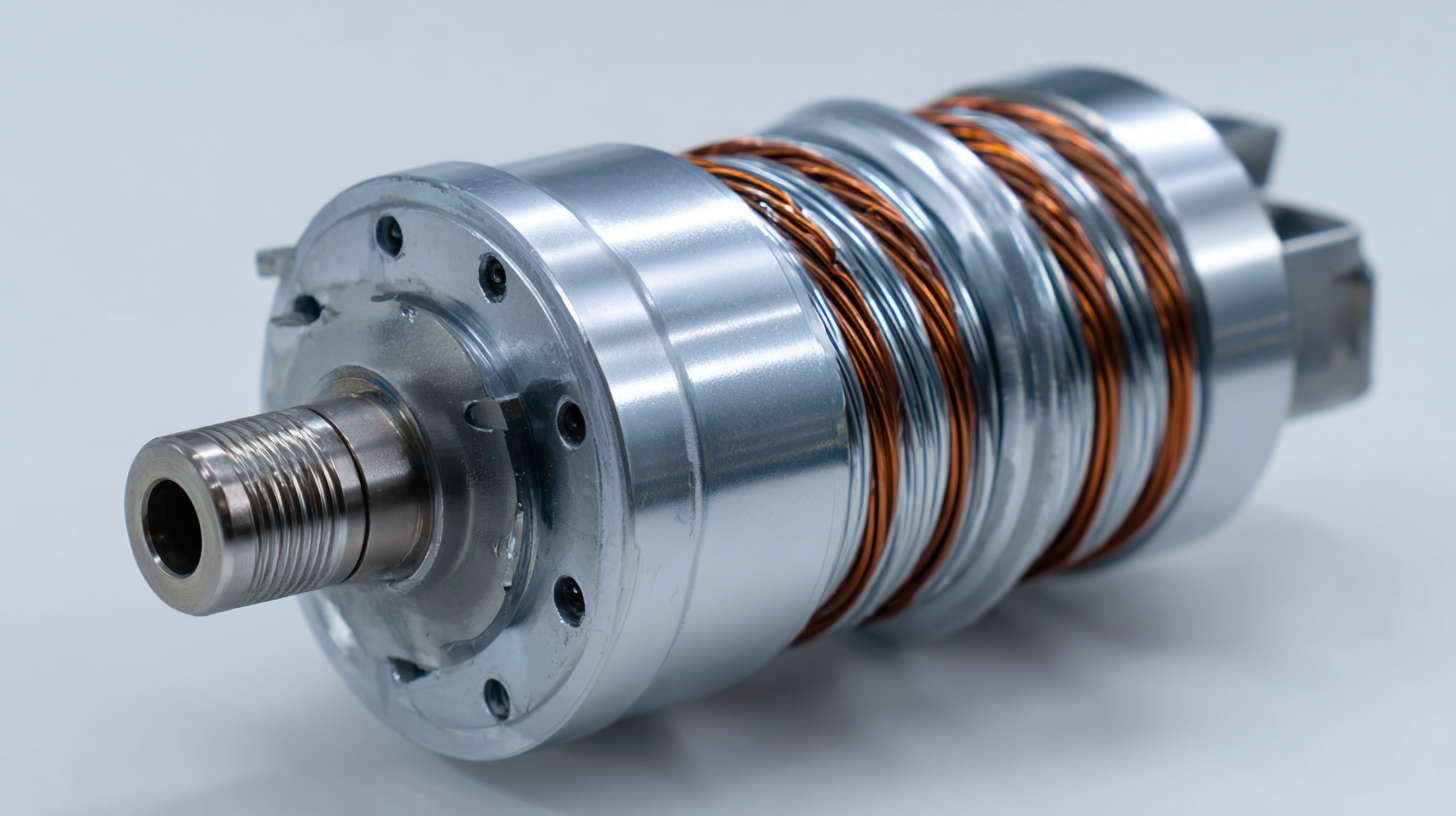

In today's rapidly evolving technological landscape, the demand for efficient and compact motor solutions is more pressing than ever. Among the various types of motors available, the frameless DC motor stands out due to its unique design and numerous advantages in modern applications. Unlike traditional motors that come with a bulky housing, frameless DC motors offer a streamlined profile that allows for greater flexibility in integration and reduced weight, making them an ideal choice for compact systems. This blog will delve into the key benefits of frameless DC motors, highlighting their superior performance, efficiency, and versatility across different industries. By understanding these advantages, engineers and designers can leverage frameless DC motors to enhance their projects and meet the challenges of today’s high-tech environments.

Frameless DC motors are gaining traction in modern applications due to their compact design and superior performance compared to traditional motors. One of the key advantages is the reduced weight and size, allowing for more flexible designs in applications like robotics and aerospace. A report by the International Electromechanical Commission suggests that frameless motors can reduce overall system weight by up to 20%, which is critical in industries where every gram counts.

Another significant benefit of frameless DC motors is their enhanced efficiency. These motors offer improved heat dissipation and have fewer components, leading to increased durability and lower maintenance costs. According to data from the Electric Motor Systems Market Report, frameless designs can improve energy efficiency by approximately 15%, directly impacting operational costs. This efficiency also translates into lower energy consumption, supporting sustainable practices in industrial applications.

Tips: When selecting a motor for your application, consider not only the power requirements but also the size constraints. Ensure compatibility with existing systems, especially if you are switching from traditional motors to frameless designs. Regular maintenance checks can also help maximize the lifespan and efficiency of your motor systems, ensuring optimal performance throughout their operational life.

Frameless DC motors are becoming increasingly pivotal in various modern applications, particularly in fields that demand precision and efficiency. These motors, known for their compact design and lightweight structure, are extensively used in robotics and automation. According to a report by ResearchAndMarkets, the global robotics market is projected to reach USD 214 billion by 2025, with frameless DC motors playing a critical role in enhancing the agility and performance of robotic systems. Their ability to fit into tight spaces and deliver high torque at low speeds makes them ideal for applications ranging from robotic arms to automated guided vehicles.

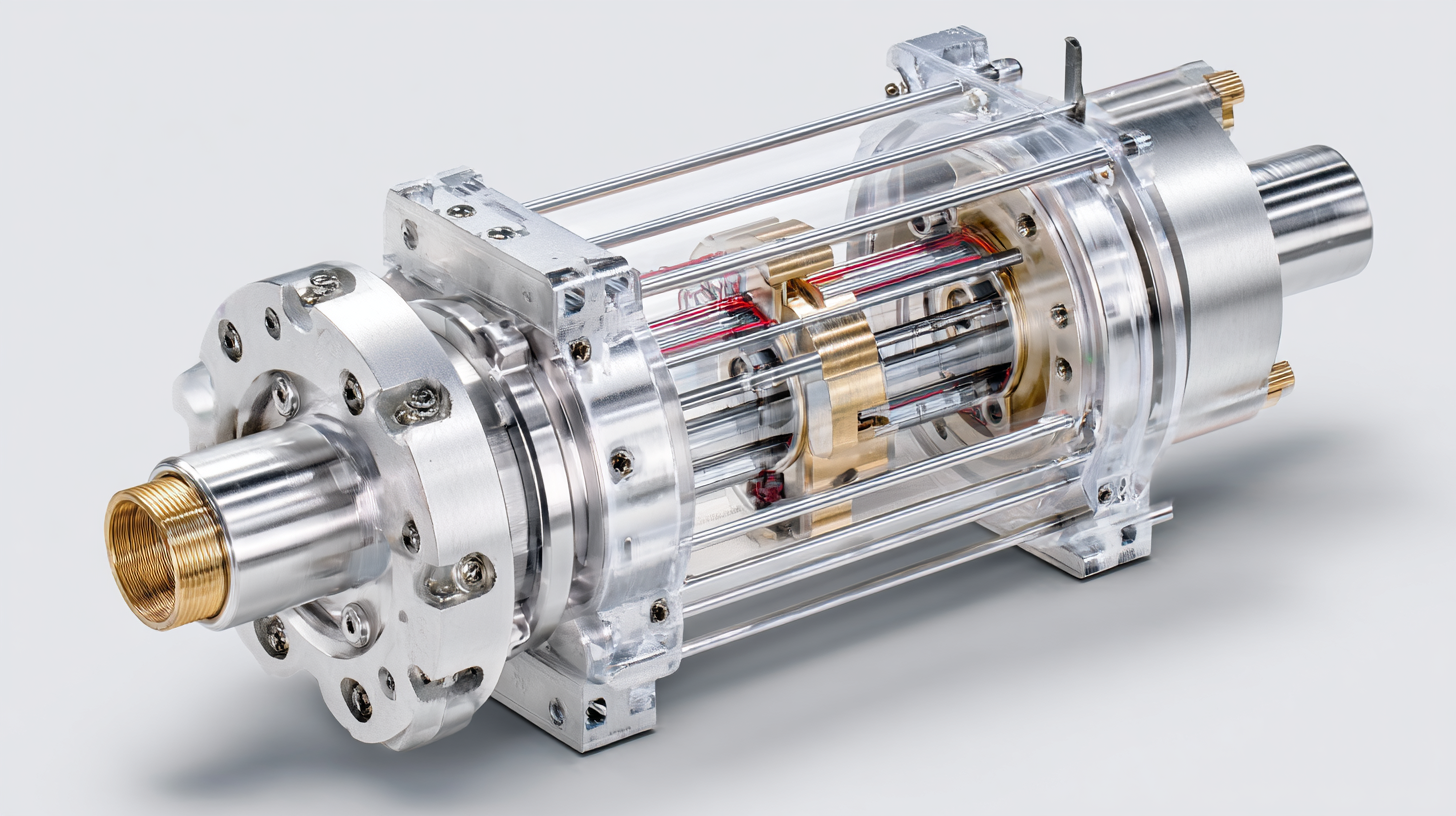

In the medical technology sector, frameless DC motors are proving essential for minimizing the size and increasing the reliability of surgical instruments. A study published by MarketsandMarkets estimates that the medical robotics market will grow from USD 5.4 billion in 2020 to USD 18.7 billion by 2025, highlighting the need for advanced motor technologies. Frameless DC motors allow for greater design flexibility, which is crucial for developing portable and minimally invasive devices. This not only enhances operational efficiency but also improves patient outcomes by enabling precise control in delicate procedures.

This chart illustrates the market demand for frameless DC motors across various key applications in modern technology. The sectors include Robotics, Medical Devices, Automotive, Aerospace, and Industrial Automation, highlighting the significant role of frameless DC motors in these industries.

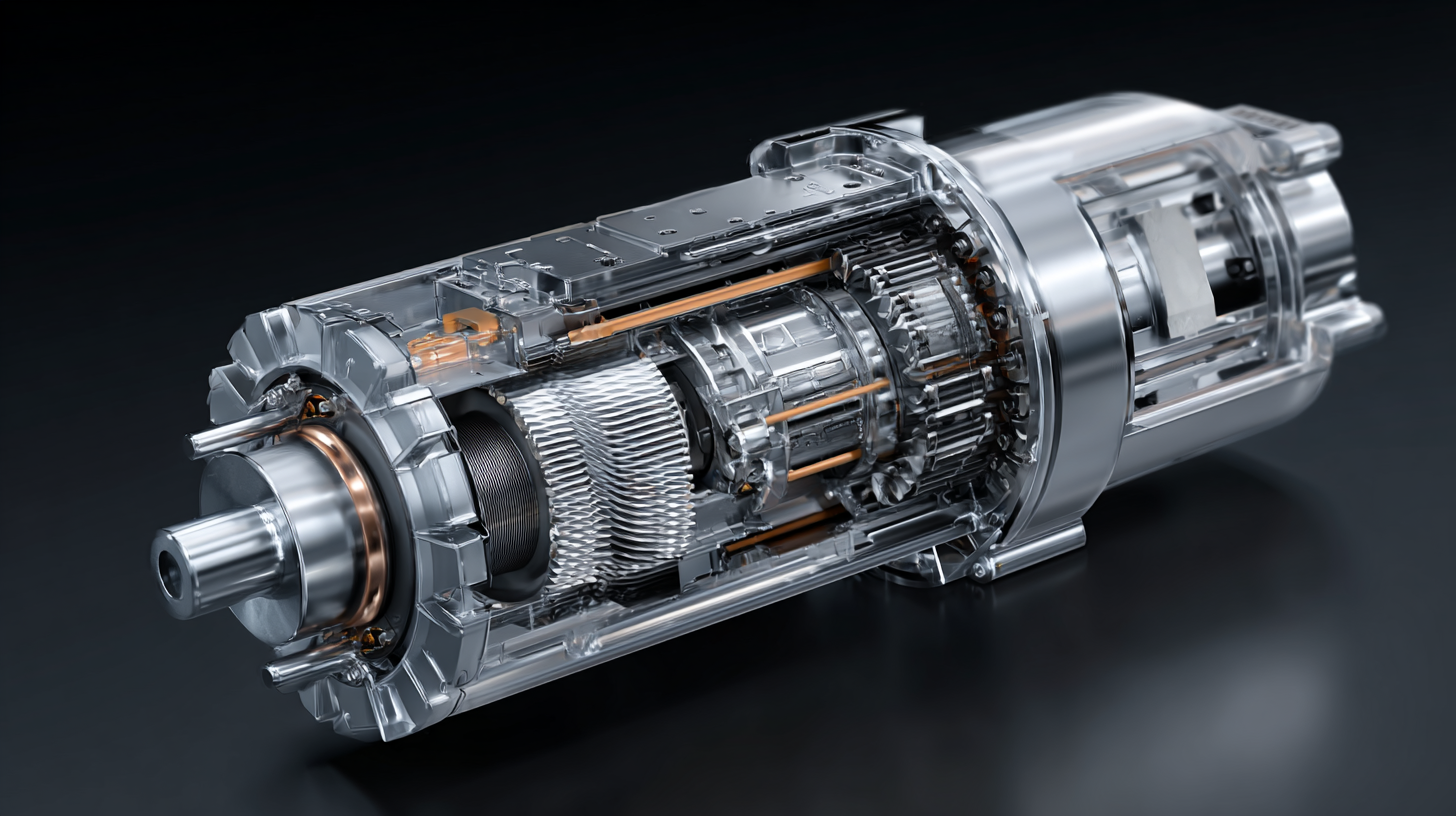

Frameless DC motors are revolutionizing modern applications with their sleek design and impressive performance capabilities. One of the key advantages of these motors is their ability to enhance efficiency, particularly in robotics and automation industries. According to a report by Allied Market Research, the global robotics market is expected to reach $210 billion by 2025, with frameless DC motors playing a critical role in developing more compact and efficient robotic solutions. The absence of a traditional frame allows for a direct integration into mechanical systems, minimizing weight and maximizing torque density, which is crucial for high-performance applications.

Furthermore, frameless DC motors significantly improve overall performance due to their superior dynamic response and control. A study by the International Journal of Electrical Engineering cited that frameless motors exhibit higher power-to-weight ratios compared to conventional motor designs, achieving efficiencies up to 95% in optimal conditions. This level of efficiency not only contributes to energy savings but also prolongs the operational lifespan of equipment, making them ideal for use in demanding environments such as aerospace and medical devices. As industries continue to demand more compact and efficient solutions, the adoption of frameless DC motors is set to accelerate, pushing the boundaries of technology and innovation.

Frameless DC motors are gaining popularity in various sectors due to their inherent design flexibility, which allows for customization to meet specific application needs. Unlike traditional motors, frameless designs provide manufacturers with the ability to integrate motors into their equipment seamlessly. This adaptability is particularly advantageous in industries such as robotics and automation, where space constraints and weight limitations are of utmost importance. A recent report from Smithers Pira highlights that frameless DC motors can reduce the overall system weight by up to 30%, enabling more efficient designs without compromising performance.

Moreover, the customization possibilities of frameless DC motors extend to performance characteristics, such as torque and speed. According to a market analysis by Research and Markets, the demand for tailored motor solutions is expected to grow by 15% annually, driven by advancements in technology and the need for specialized applications. Designers can adjust parameters such as winding configurations and magnet types to create motors optimized for their unique operating environments. As industries continue to evolve, the ability to create highly specialized, frameless DC motors will be crucial in maintaining a competitive edge and enhancing overall system functionality.

| Feature | Description | Advantage |

|---|---|---|

| Compact Design | Eliminates additional housing and support systems. | Saves space, allowing for more compact product designs. |

| High Performance | Offers excellent torque-to-weight ratios and efficiency. | Delivers more power without increasing size or weight. |

| Customization | Can be tailored to specific application requirements. | Enhances compatibility with various automation tasks. |

| Reduced Noise | Minimizes operational noise compared to traditional motors. | Improves user experience in noise-sensitive environments. |

| Ease of Integration | Designed for seamless integration into existing systems. | Reduces implementation time and cost for projects. |

Frameless DC motors are increasingly becoming a focal point in modern engineering due to their compact design and high performance. As industries demand more efficient and space-saving solutions, innovation in frameless DC motor technology is set to advance significantly. According to a report by MarketsandMarkets, the global DC motor market is projected to reach $27.92 billion by 2027, with frameless designs facilitating enhanced performance across various sectors, including robotics, aerospace, and medical devices.

Looking ahead, several trends are poised to transform the frameless DC motor landscape. One promising innovation is the integration of advanced materials, such as carbon nanotubes and high-temperature superconductors, which can increase efficiency and reduce weight. Additionally, the incorporation of smart technologies, including AI-driven control systems, can optimize motor performance in real-time, enhancing their adaptability in dynamic applications. As these advancements unfold, the role of frameless DC motors in applications ranging from electric vehicles to precise medical instruments will continue to grow, highlighting their critical contribution to the future of motion control solutions.