The integration of Brushless DC Electric Motors in modern robotics and automation has revolutionized the way industries operate, offering significant advantages over traditional motor systems. As noted in the 2022 report by the International Federation of Robotics, approximately 38% of all industrial robots utilize brushless DC technology, highlighting its growing prominence in automated solutions.

These motors provide superior efficiency, reduced maintenance requirements, and enhanced performance characteristics, making them ideal for applications ranging from assembly lines to precision robotic arms.

With a projected market growth rate of 7.5% annually through 2028 according to Research and Markets, the adoption of Brushless DC Electric Motors is not just a trend, but a key driver of innovation and productivity in robotics and automation.

This article will explore the various benefits these motors bring to the table, emphasizing their role in shaping the future of automation technologies.

The integration of Brushless DC Electric Motors in modern robotics and automation has revolutionized the way industries operate, offering significant advantages over traditional motor systems. As noted in the 2022 report by the International Federation of Robotics, approximately 38% of all industrial robots utilize brushless DC technology, highlighting its growing prominence in automated solutions.

These motors provide superior efficiency, reduced maintenance requirements, and enhanced performance characteristics, making them ideal for applications ranging from assembly lines to precision robotic arms.

With a projected market growth rate of 7.5% annually through 2028 according to Research and Markets, the adoption of Brushless DC Electric Motors is not just a trend, but a key driver of innovation and productivity in robotics and automation.

This article will explore the various benefits these motors bring to the table, emphasizing their role in shaping the future of automation technologies.

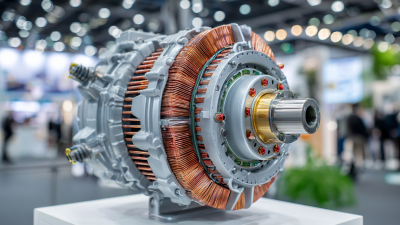

Brushless DC motors (BLDC) have become increasingly popular in robotics and automation, particularly due to their numerous advantages over traditional brushed motors. BLDC motors are known for their higher efficiency and greater reliability, which leads to increased performance in applications like humanoid robots. Their design eliminates the need for brushes, which reduces maintenance and enhances durability, making them an ideal choice for long-term robotic operations. The higher torque density of BLDC motors also allows for more compact designs, enabling manufacturers to create smaller, more agile robots.

Brushless DC motors (BLDC) have become increasingly popular in robotics and automation, particularly due to their numerous advantages over traditional brushed motors. BLDC motors are known for their higher efficiency and greater reliability, which leads to increased performance in applications like humanoid robots. Their design eliminates the need for brushes, which reduces maintenance and enhances durability, making them an ideal choice for long-term robotic operations. The higher torque density of BLDC motors also allows for more compact designs, enabling manufacturers to create smaller, more agile robots.

Furthermore, the growing demand for advanced robotic solutions is reflected in the projected growth of the global brushless DC motor market, which is expected to reach USD 20.68 billion by 2030. As automation becomes increasingly integral to various industries, including agriculture and manufacturing, the unique characteristics of BLDC motors—such as their quiet operation and smooth performance—make them a preferred option. Designers are also recognizing the potential of these motors in the development of energy-efficient systems, paving the way for smarter and more effective robotic technologies.

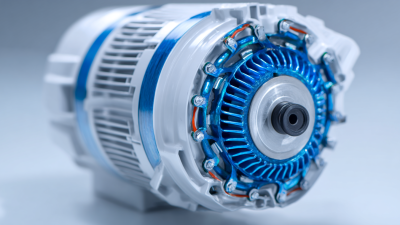

Brushless DC (BLDC) motors have emerged as a pivotal technology in the realm of modern robotics and automation, primarily driven by their enhanced efficiency and performance. According to recent market analyses, the brushless DC motor market is projected to soar to approximately USD 66.57 billion by 2033, reflecting a robust CAGR of 11.63% from 2025 to 2033. This remarkable growth underscores the increasing adoption of BLDC motors in various sectors, including automotive and industrial automation, due to their superior operational characteristics.

The demand for energy-efficient motors is a key factor propelling this trend. BLDC motors are engineered to maximize efficiency and torque density, which significantly reduces energy consumption—a critical consideration in today’s eco-conscious industrial landscape. Reports indicate a substantial shift towards higher-efficiency motor classifications, with the industrial motor market expected to witness a growth of 6.6% CAGR, reaching USD 285.9 billion by 2035. Innovative rotor designs further enhance motor performance, allowing for unprecedented capabilities in applications requiring precision and reliability. This shift not only drives performance improvements but also aligns with the growing emphasis on sustainability in industrial practices.

Brushless DC motors have emerged as pivotal components in the realm of robotics and automation, primarily due to their efficiency and low maintenance requirements. Unlike their brushed counterparts, brushless motors utilize electronic commutation, which significantly reduces wear and tear, leading to a longer operational lifespan. This attribute is essential in high-demand applications within robotics, where consistent performance and reliability are critical.

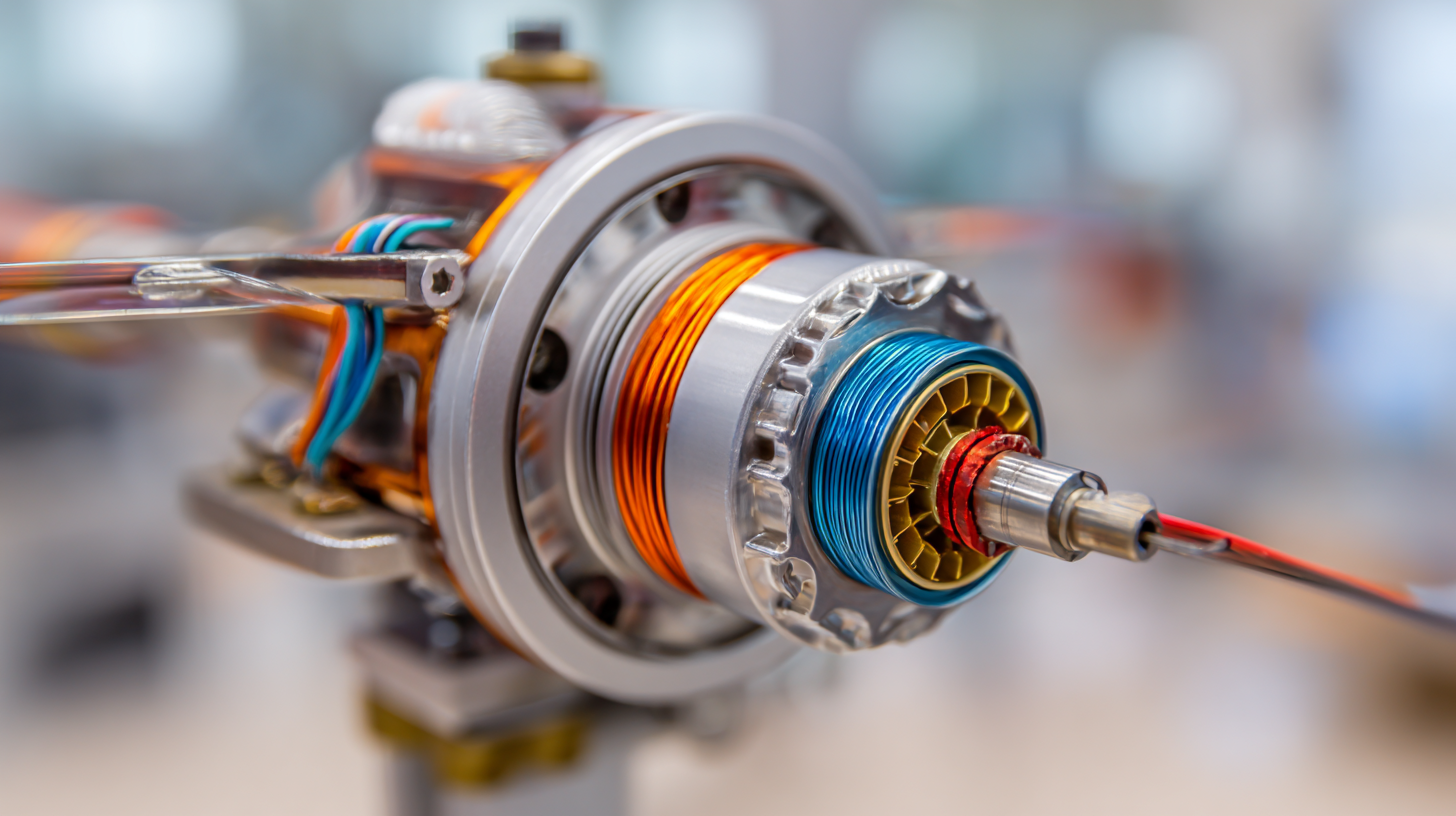

Key applications of brushless DC motors in robotics include their use in humanoid robots, drones, and precision automation systems. In humanoid robots, these motors enable smooth and precise movements, mimicking human motion with high accuracy. Furthermore, in the context of drones, brushless motors provide the necessary thrust and flight stability while maintaining energy efficiency, which is vital for enhancing flight times. As industries increasingly adopt automation technologies, the role of brushless DC motors continues to expand, highlighting their integral part in driving innovation and efficiency in modern robotic applications.

Brushless DC (BLDC) motors are becoming increasingly vital in robotics and automation, particularly in enhancing energy efficiency and sustainability. A report by the International Energy Agency (IEA) indicates that electric motors consume approximately 40% of global electricity, highlighting the need for more efficient solutions. BLDC motors offer efficiency levels that can exceed 90%, significantly reducing energy consumption during operation. This remarkable efficiency not only lowers operating costs but also diminishes the environmental impact associated with energy production.

Moreover, the adoption of BLDC motors can lead to substantial reductions in greenhouse gas emissions. According to a study by the U.S. Department of Energy, the widespread use of high-efficiency motors like BLDC can potentially result in energy savings of up to 50 billion kilowatt-hours annually in the United States alone. This reduction translates to approximately 40 million metric tons of CO2 emissions, underscoring the motors' role in promoting sustainability. Aligning with global goals for reducing energy footprint, BLDC motors represent a crucial advancement in making robotics and automation systems not only smarter but also more environmentally friendly.

| Feature | Brushless DC Motors | Traditional DC Motors |

|---|---|---|

| Efficiency | 85-90% | 75-80% |

| Maintenance | Low | Moderate to High |

| Power Density | High | Lower |

| Heat Generation | Low | Higher |

| Environmental Impact | Lower carbon footprint due to efficiency | Higher due to energy loss |

| Cost | Higher initial investment | Lower initial investment |

The future of brushless DC (BLDC) motor technology is poised for tremendous growth in advanced robotics, driven by ongoing advancements in control algorithms and materials. According to a recent report by MarketsandMarkets, the global brushless motor market is expected to reach $25.12 billion by 2025, growing at a CAGR of 7.65%. This surge indicates that BLDC motors are becoming increasingly vital in sectors such as medical robotics, industrial automation, and autonomous vehicles, where precision and efficiency are paramount. The continuous improvements in energy density, reliability, and integration with smart technologies are further accelerating this trend.

As robotics applications become more sophisticated, the demand for high-performance motors is intensifying. Advanced manufacturing processes, such as 3D printing of motor components and the use of artificial intelligence for predictive maintenance, are enhancing the capabilities of BLDC motors. Innovations like sensorless control mechanisms are leading to reduced costs and simpler designs, making them more accessible for small to medium enterprises aiming to automate operations.

Tip: When selecting a brushless DC motor for robotics applications, consider the torque-to-weight ratio, as this can greatly influence the performance and efficiency of your robotic systems.

Furthermore, the integration of IoT with motor technology offers real-time monitoring and data analytics, allowing for smarter robotics solutions. Further exploring these technologies can reveal not only potential cost savings but also improvements in operational efficiency and productivity.

Tip: Ensure compatibility with existing systems before upgrading to the latest BLDC motor technologies to maximize your investment and streamline integration processes.